I'm installing my Touch DRO with Aikron scales and have two questions about the optical scale.

1) The reader head came mounted on the scale. There are red clips attached to each end of the scale, each extends about 30mm away from the reader.

My assumption is that these clips are used to keep the read head in place during installation and that they are removed when the install is complete. I'm fairly positive they can't stay in place (since they would reduce the travel by ~60 mm and the travel won't equal the distance ordered (and shipped).

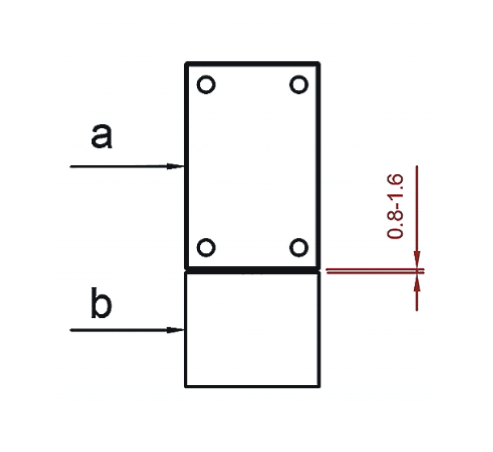

The instructions mention removing a "pad block and has this illustation (which doesn't help me at all):

1) The reader head came mounted on the scale. There are red clips attached to each end of the scale, each extends about 30mm away from the reader.

My assumption is that these clips are used to keep the read head in place during installation and that they are removed when the install is complete. I'm fairly positive they can't stay in place (since they would reduce the travel by ~60 mm and the travel won't equal the distance ordered (and shipped).

The instructions mention removing a "pad block and has this illustation (which doesn't help me at all):

Standard of reading head installation

1.The clearance between the reading head and the height direction of the ruler

body is 0.8mm-1.6mm after installation, and then withdraw the pad block

Am I on the right track?

My second question pertains to the interface. Since I have a mag scale on the cross slide and those only come with RS422, I ordered RS422 on the optical one as well. But despite ordering 5 micron RS422, some of the paperwork indicates 1 micron and TTL. I can get this working by trying both options, but I wanted to make sure that I won't burn anything out if I try RS422 and it's really TTL. Or vice versa. If it's safe to try one first and not the other...that would be really good to know!