Hey y'all!

I just finished pulling apart, cleaning, and re-greasing my Unimat DB200 headstock spindle, and now when I run it, I'm getting a high-pitched sound coming out of the chuck side.

I followed instructions and put everything back in order, re-greased the bearings (SuperLube), etc. and don't know why it would be making this sound (the sound was not present before rebuilding). The sound gets louder when I tighten the lock nut any more than hand tight.

I'm wondering if this might be an issue with the bearings and races OR maybe the preload washers not doing their job? Maybe too much grease in the bearings?

Any help would be greatly appreciated!

Thanks,

Tony

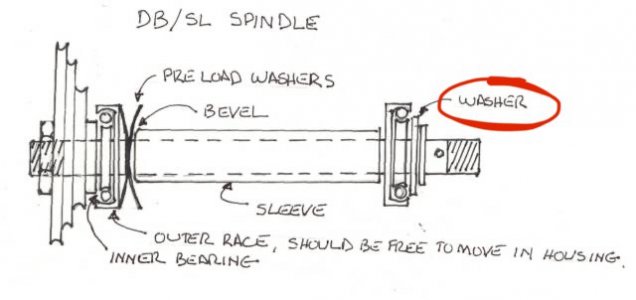

I think I should also note that when disassembling the lathe, I appear to be missing (?) this washer (image below). Not sure if this was present on some lathes and not others, but wanted to make a note.

I just finished pulling apart, cleaning, and re-greasing my Unimat DB200 headstock spindle, and now when I run it, I'm getting a high-pitched sound coming out of the chuck side.

I followed instructions and put everything back in order, re-greased the bearings (SuperLube), etc. and don't know why it would be making this sound (the sound was not present before rebuilding). The sound gets louder when I tighten the lock nut any more than hand tight.

I'm wondering if this might be an issue with the bearings and races OR maybe the preload washers not doing their job? Maybe too much grease in the bearings?

Any help would be greatly appreciated!

Thanks,

Tony

I think I should also note that when disassembling the lathe, I appear to be missing (?) this washer (image below). Not sure if this was present on some lathes and not others, but wanted to make a note.

Attachments

Last edited: