- Joined

- Jul 7, 2020

- Messages

- 71

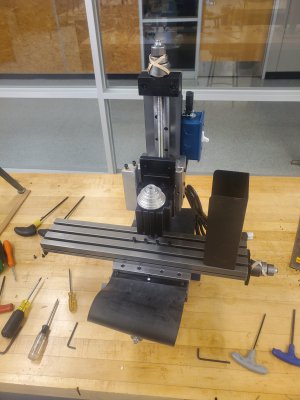

I just had this delivered to the University. I wanted a smaller CNC mill for my polymers area that could be used for making small injection molds and dies for ceramic pressing. We currently have two other CNC mills back there, one is a Sherline and the other is a very nice Wabeco. So far I am impressed with what I see on this mill and Taig's packaging and service are top notch. It is much heavier than the Sherline mill we have (also a nice machine) and with half inch ball screws on the XYZ axis it should prove to be very accurate. I also ordered it with a 4th axis and 3-jaw chuck. We ordered a new Taig CNC lathe this week with the 5C headstock also with ball screws. I am looking forward to seeing that as well.

We have much heavier CNC equipment in our metal labs, but I like to keep some of the smaller machines separate from these and I have found these to be good trainers before students move up to our Haas and other maching centers.

We have much heavier CNC equipment in our metal labs, but I like to keep some of the smaller machines separate from these and I have found these to be good trainers before students move up to our Haas and other maching centers.

Attachments

-

20200710_155920.jpg1.3 MB · Views: 35

20200710_155920.jpg1.3 MB · Views: 35 -

20200710_151449.jpg1.4 MB · Views: 35

20200710_151449.jpg1.4 MB · Views: 35 -

20200710_151434.jpg1.5 MB · Views: 32

20200710_151434.jpg1.5 MB · Views: 32 -

20200710_143225.jpg1.6 MB · Views: 27

20200710_143225.jpg1.6 MB · Views: 27 -

20200710_143214.jpg1.6 MB · Views: 26

20200710_143214.jpg1.6 MB · Views: 26 -

20200710_141415.jpg3 MB · Views: 26

20200710_141415.jpg3 MB · Views: 26 -

20200710_141408.jpg3 MB · Views: 24

20200710_141408.jpg3 MB · Views: 24 -

20200710_125924.jpg3.2 MB · Views: 25

20200710_125924.jpg3.2 MB · Views: 25 -

20200710_125918.jpg2.9 MB · Views: 25

20200710_125918.jpg2.9 MB · Views: 25 -

20200710_125907.jpg3 MB · Views: 27

20200710_125907.jpg3 MB · Views: 27 -

20200710_125902.jpg3.3 MB · Views: 25

20200710_125902.jpg3.3 MB · Views: 25 -

20200710_125854.jpg3.2 MB · Views: 31

20200710_125854.jpg3.2 MB · Views: 31