- Joined

- Oct 17, 2018

- Messages

- 922

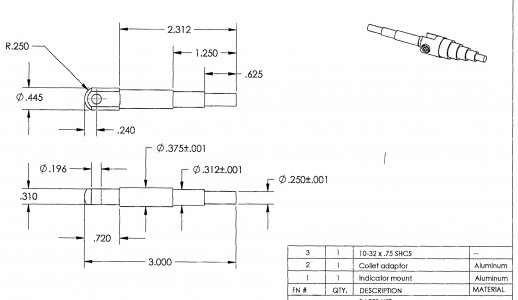

I'm making a cylindrical part that will require the use of a collet block because I have to mill a slot on the end, then drill and tap a hole perpendicular to the slot. My vise jaws are 1" high. This seems like it will not adequately support the work standing on end. So, I'm thinking I'll need to clamp the collet block to a right-angle fixture (properly aligned) for the slot, mill the slot, then rotate the block, re-clamp it to the right-angle fixture, and drill the hole.

Anyone ever done an operation like this on a smaller mill? Is my thinking sound/safe? I have an LMS 3990 mill.

Anyone ever done an operation like this on a smaller mill? Is my thinking sound/safe? I have an LMS 3990 mill.