I've acquired a set of various size round boring bars with square holes for hss tool bit. Hole on one side positions the bit at 90 degrees to bar axis and the other end at an angle. As I have a box of hand me down hss blanks. I'd like to use these rather than buying more boring bars of the insert or cemented carbide variety.

I've looked at the profiles of cemented carbide boring bars and reviewed the "Boring Primer" on the forum. As I understand, my exposed end of a hss tool bit should be as short as possible, have a small nose radius, a neutral or slightly positive lead angle ( angled back away from cutting direction for tight tolerance), adequate relief from part radius, a relief on end away from cut surface, and zero or slightly positive back rake ( away from radius). However this is my understanding for cemented carbide and inserts from reading the primer.

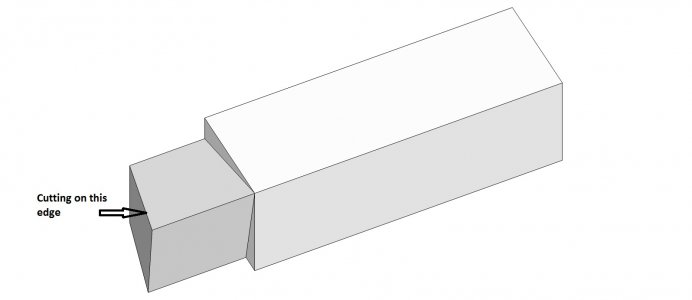

Should the geometry I grind into HSS be the same? Secondly, should I be using the 90 degree slot or the angled slot in these boring bars?

Thanks

I've looked at the profiles of cemented carbide boring bars and reviewed the "Boring Primer" on the forum. As I understand, my exposed end of a hss tool bit should be as short as possible, have a small nose radius, a neutral or slightly positive lead angle ( angled back away from cutting direction for tight tolerance), adequate relief from part radius, a relief on end away from cut surface, and zero or slightly positive back rake ( away from radius). However this is my understanding for cemented carbide and inserts from reading the primer.

Should the geometry I grind into HSS be the same? Secondly, should I be using the 90 degree slot or the angled slot in these boring bars?

Thanks