- Joined

- Oct 16, 2017

- Messages

- 338

I did not find much info on this site about this particular brand so I thought I would share some thoughts and pictures.

I was interested in a sort of do it all (horizontal/vertical rotary table + spindexer + super spacer). Two machines that seemed to combine the worst of all three that were in my price range were the Grizzly H7506 (China) and the Vertex CS-6 (Taiwan). Not sure why I picked the Vertex, it is about the same price as the Grizzly. Vertex makes an 8" version (CS-8) but did not want to wrestle around that much weight. I monitored ebay for months looking for a used unit with similar functionality but saw none.

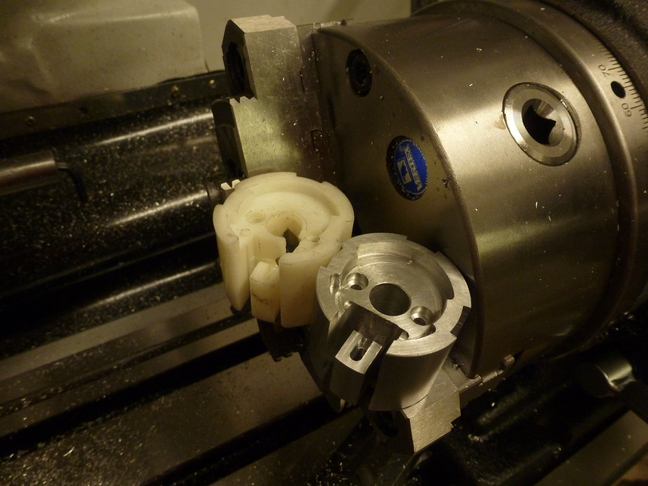

A small job reproducing a part of a plastic A/V fixture that kept breaking cropped up that expedited getting a rotary solution for my milling machine:

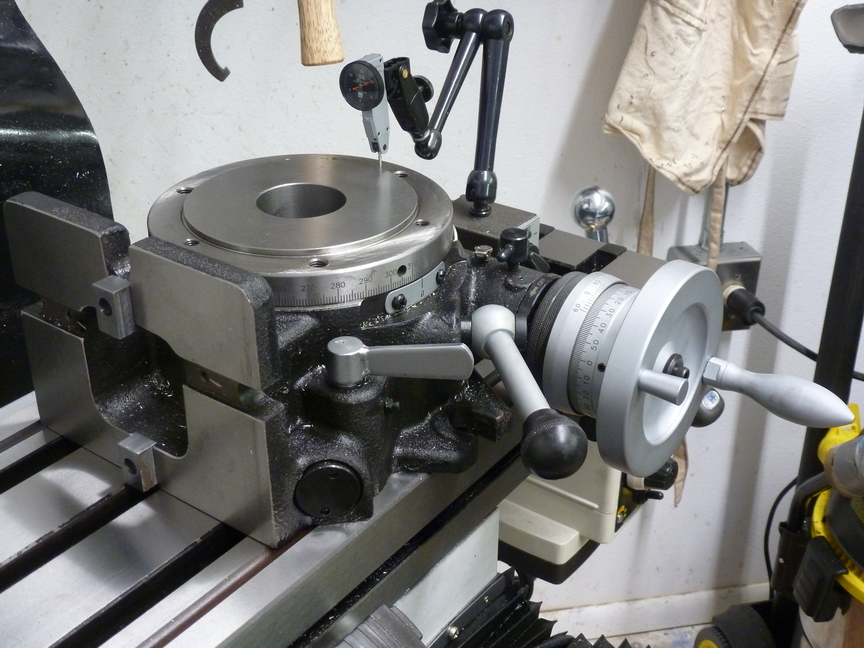

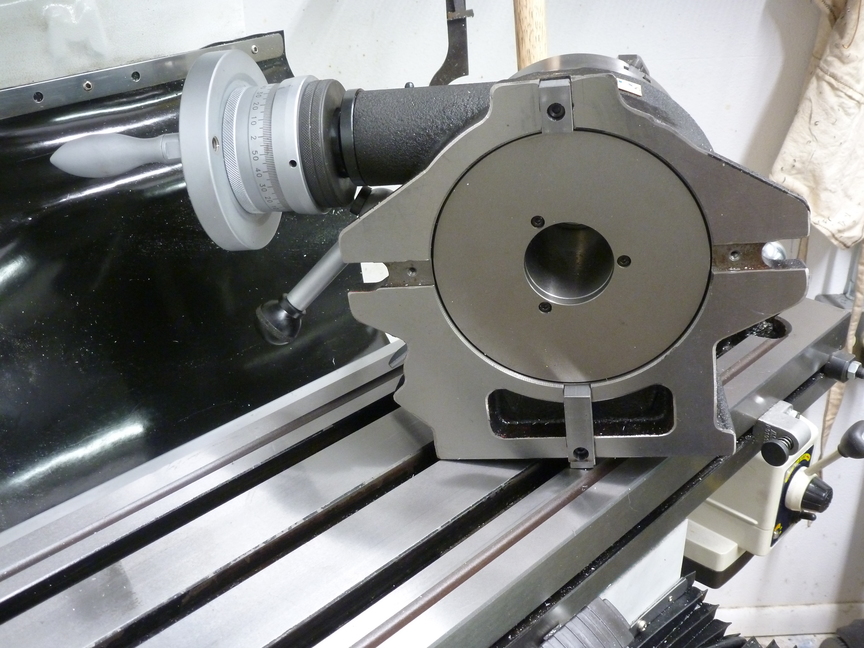

Overall it am pleased with the Vertex. The fit and finish are good and operation is smooth and repeatable. Everything lines up. Chuck is 6" with less than 0.001" run out. For perspective this is mounted on the PM935 manual mill.

The Vertex did not come with alignment keys.

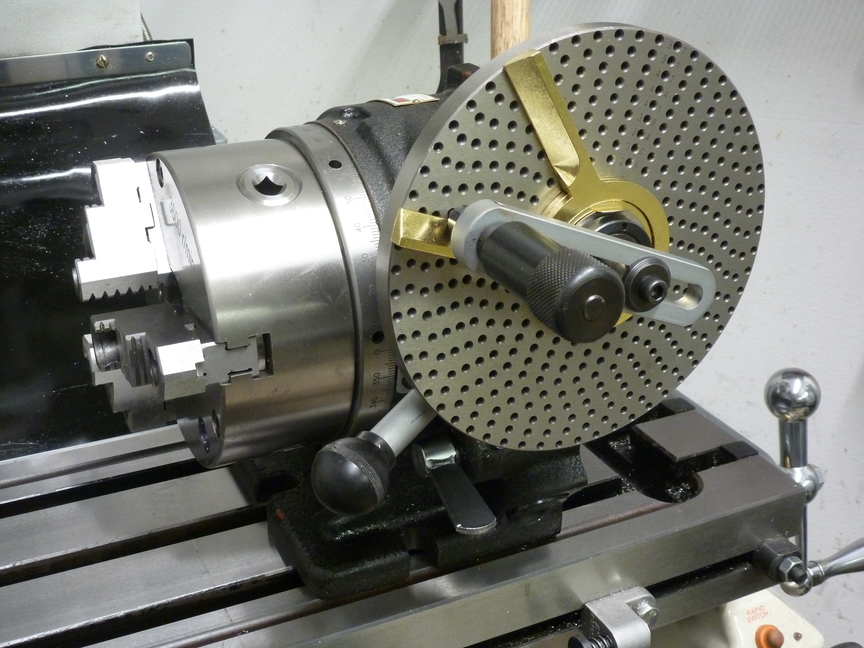

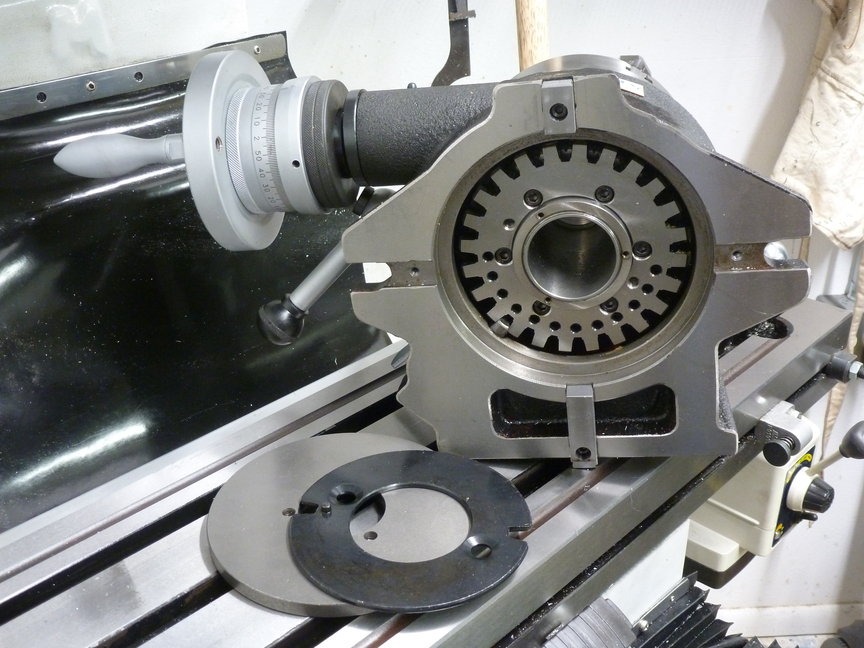

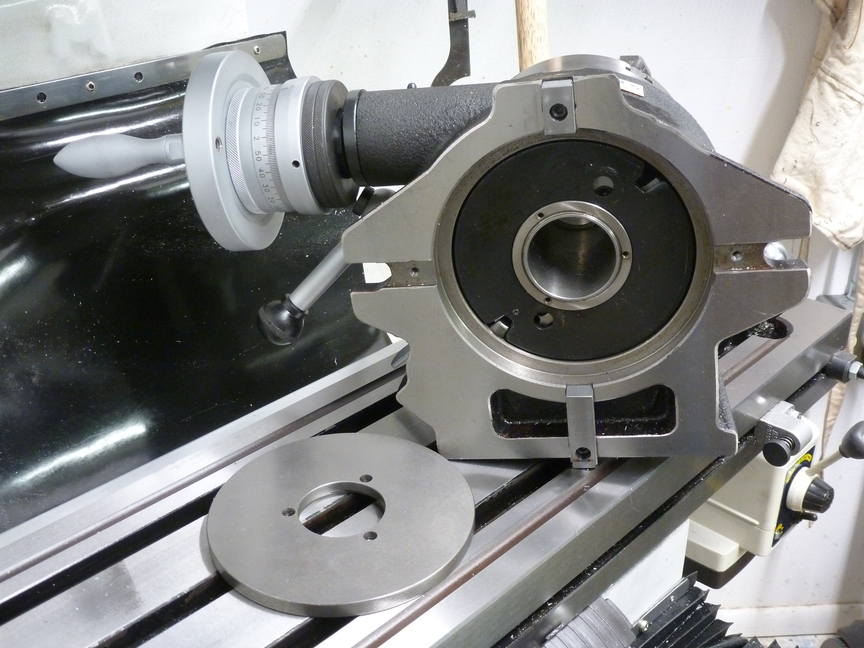

Set up for the indexing attachment (sold separately) was straight forward. The tolerance are very tight. One sad note is that sector arms, although gold in color, are mystery metal rather that brass (I think I will made a set now that can). I had to reorient the spindle lock to clear the masking plate. The drive ratio is 90:1 (4 deg per revolution). I have attached a 90:1 dividing head table for the set of plates (2) that came with the attachment.

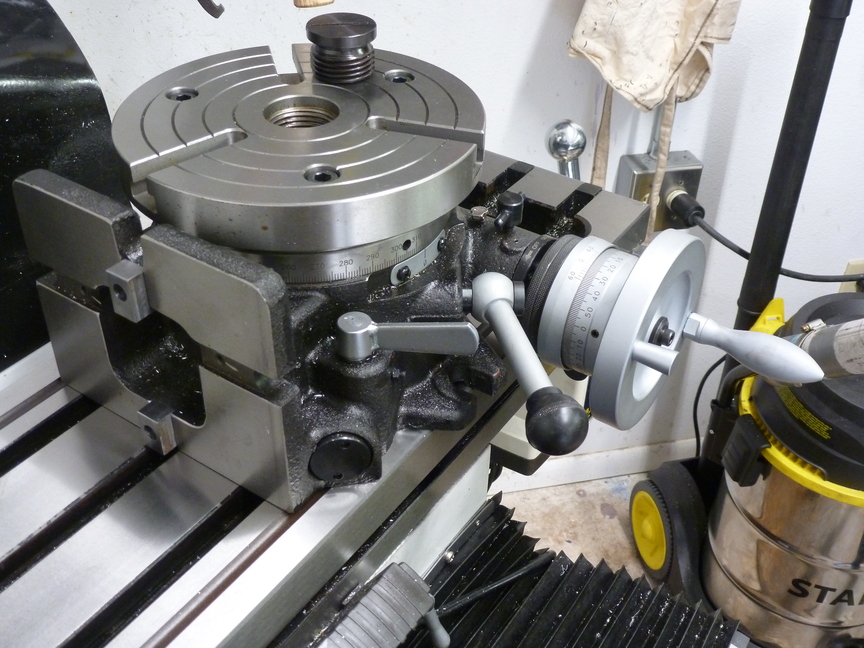

I measured <0.0005" chuck/RT boss run out.

Rotary table is 8" and will come in handy. The table surface is clear of the base allowing full use.

Masking plates are 2, 3, 4, 6, 8, 12 and 24 internal. A significant draw back with this machine is the inability to disengage and lock the masking pin retract lever. Hence your thumb is on the masking pin lever while milling, not ideal. I think I will add a feature to this mechanism to allow locking or maybe it exists and I have not yet figured it out (user manual is pretty sketchy).

I was interested in a sort of do it all (horizontal/vertical rotary table + spindexer + super spacer). Two machines that seemed to combine the worst of all three that were in my price range were the Grizzly H7506 (China) and the Vertex CS-6 (Taiwan). Not sure why I picked the Vertex, it is about the same price as the Grizzly. Vertex makes an 8" version (CS-8) but did not want to wrestle around that much weight. I monitored ebay for months looking for a used unit with similar functionality but saw none.

A small job reproducing a part of a plastic A/V fixture that kept breaking cropped up that expedited getting a rotary solution for my milling machine:

Overall it am pleased with the Vertex. The fit and finish are good and operation is smooth and repeatable. Everything lines up. Chuck is 6" with less than 0.001" run out. For perspective this is mounted on the PM935 manual mill.

The Vertex did not come with alignment keys.

Set up for the indexing attachment (sold separately) was straight forward. The tolerance are very tight. One sad note is that sector arms, although gold in color, are mystery metal rather that brass (I think I will made a set now that can). I had to reorient the spindle lock to clear the masking plate. The drive ratio is 90:1 (4 deg per revolution). I have attached a 90:1 dividing head table for the set of plates (2) that came with the attachment.

I measured <0.0005" chuck/RT boss run out.

Rotary table is 8" and will come in handy. The table surface is clear of the base allowing full use.

Masking plates are 2, 3, 4, 6, 8, 12 and 24 internal. A significant draw back with this machine is the inability to disengage and lock the masking pin retract lever. Hence your thumb is on the masking pin lever while milling, not ideal. I think I will add a feature to this mechanism to allow locking or maybe it exists and I have not yet figured it out (user manual is pretty sketchy).

Attachments

Last edited: