- Joined

- Dec 15, 2022

- Messages

- 65

I just completed the alignment of my tailstock on a PM-1130v: I have it running within a half thou over 8 1/2" inches which seems plenty good enough to me. But the direction of adjustment on the tailstock makes no sense to me. Prior to the TS aligning, I leveled the ways of the lathe and have it also running very well.

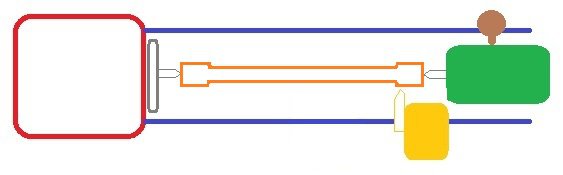

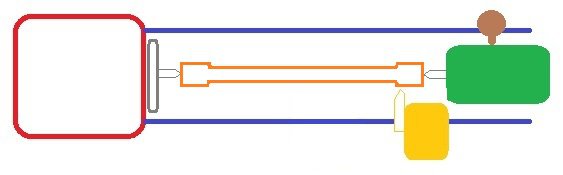

I've include a kindergarten drawing of my lathe (oh the colors!) to help with the discussion -

I turned a test bar (orange) between dead centers and took a reading - the TS end of the bar was smaller by 7 thou. To me this means that the tool (yellow) is closer to the work at the tail end (green) and farther away at the headstock end (red). I had an indicator (brown) attached to the backsplash and indicating against the TS so I adjusted it about 3.5 thou closer to the indicator (upward in my picture).

I did another pass, mic'd the bar and this time I was nearly 12 thou out?!? Trusting the indicator, I readjusted away from the indicator (downward in my picture) which, to me, would bring the test bar even closer to the toolpost. I took another pass on the test bar and mic'd again - this time I was very close.

Assuming I have the ways (blue) level, how can this be? Either I'm completing misunderstanding how this works or there's a deeper problem.

After all this fun, I remounted the 3-jaw and turned a part using the tailstock... I am indeed cutting pretty straight. This is great, but I'm super confused...

I've include a kindergarten drawing of my lathe (oh the colors!) to help with the discussion -

I turned a test bar (orange) between dead centers and took a reading - the TS end of the bar was smaller by 7 thou. To me this means that the tool (yellow) is closer to the work at the tail end (green) and farther away at the headstock end (red). I had an indicator (brown) attached to the backsplash and indicating against the TS so I adjusted it about 3.5 thou closer to the indicator (upward in my picture).

I did another pass, mic'd the bar and this time I was nearly 12 thou out?!? Trusting the indicator, I readjusted away from the indicator (downward in my picture) which, to me, would bring the test bar even closer to the toolpost. I took another pass on the test bar and mic'd again - this time I was very close.

Assuming I have the ways (blue) level, how can this be? Either I'm completing misunderstanding how this works or there's a deeper problem.

After all this fun, I remounted the 3-jaw and turned a part using the tailstock... I am indeed cutting pretty straight. This is great, but I'm super confused...