I posted this but put it in the post for "Welcomes and Introductions", so not only am I new to machining, but also to navigating the forum. Sorry for the repetition, but maybe now I am in the right spot.

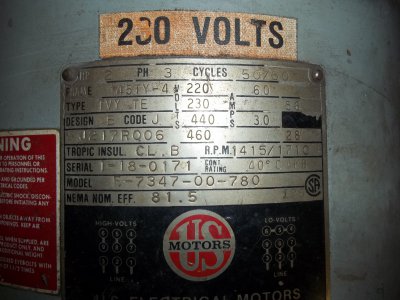

Hey everyone, I have been reading the posts as a guest, and have become convinced to start machining as a hobby. Through my online research, I decided to get a Bridgeport (2J head) and hook it to a VFD to go from single phase 220. The mill I bought worked fine in the shop where I bought it (Massachusetts) where it was hooked to 3 phase, I then loaded it up and took it home to Texas which was around 2000 miles. I put it in my shop and hooked it up to a VFD. However, I hooked it up through the Bridgeport switch (which I know now was the wrong thing to do - especially after hearing the unwanted "crack/pop" then getting to smell the vfd components burn). So now I am on vfd #2 and I hooked it up directly to the motor. Now when I turn on the vfd and push "run" I hear a fan start up (i am assuming a cooling fan within the motor), but the motor does not turn. I removed the cover on top of the motor, exposing the top of the motor, and when I hit "run" the motor starts to turn (about 1/4") then does nothing as if not enough power. The vfd I have is rated for 3HP, and my motor is 2HP. The factory setting on the vfd is set for 400 HZ, and I reset it to 50 HZ to start, once it didn't work, I put it back to 400 and I could hear the cooling motor really wind up as if were going to take off, but the motor still wouldn't run. I am concerned that I may have fried the motor when I hooked it up initially with the first vfd. Also, I rotated the head 180 degrees (upside down) for transport to reduce overall height, could this have screwed it up?

Thanks in advance for the help - through my reading of the posts, I know that there is a wealth of knowledge on this forum that can steer me in the right direction.

Hey everyone, I have been reading the posts as a guest, and have become convinced to start machining as a hobby. Through my online research, I decided to get a Bridgeport (2J head) and hook it to a VFD to go from single phase 220. The mill I bought worked fine in the shop where I bought it (Massachusetts) where it was hooked to 3 phase, I then loaded it up and took it home to Texas which was around 2000 miles. I put it in my shop and hooked it up to a VFD. However, I hooked it up through the Bridgeport switch (which I know now was the wrong thing to do - especially after hearing the unwanted "crack/pop" then getting to smell the vfd components burn). So now I am on vfd #2 and I hooked it up directly to the motor. Now when I turn on the vfd and push "run" I hear a fan start up (i am assuming a cooling fan within the motor), but the motor does not turn. I removed the cover on top of the motor, exposing the top of the motor, and when I hit "run" the motor starts to turn (about 1/4") then does nothing as if not enough power. The vfd I have is rated for 3HP, and my motor is 2HP. The factory setting on the vfd is set for 400 HZ, and I reset it to 50 HZ to start, once it didn't work, I put it back to 400 and I could hear the cooling motor really wind up as if were going to take off, but the motor still wouldn't run. I am concerned that I may have fried the motor when I hooked it up initially with the first vfd. Also, I rotated the head 180 degrees (upside down) for transport to reduce overall height, could this have screwed it up?

Thanks in advance for the help - through my reading of the posts, I know that there is a wealth of knowledge on this forum that can steer me in the right direction.