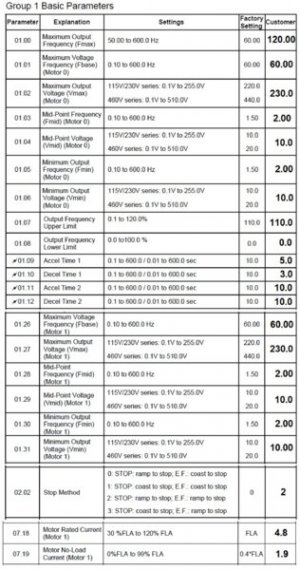

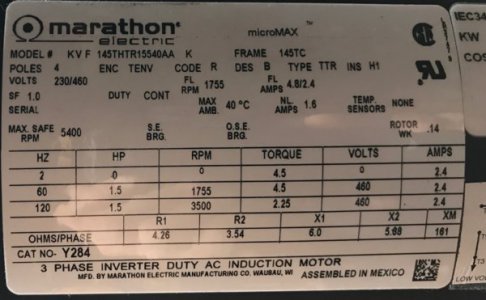

I need some advice tuning my VFD to my inverter motor. I've been running it at 60HZ but wish to run the VFD at 120HZ for double the rpm.

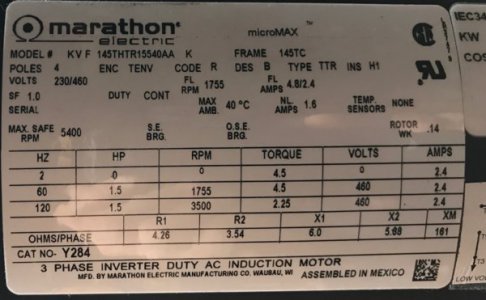

I have a Delta VFD-E ( 230V ) and a Marathon Inverter motor ( this is a different motor than what came with the mill ). Its working "ok" with the original default settings ( that were for the original motor ) at 60HZ but I just replaced the spindle bearings in my mill so they can now handle 7000 rpm ( with my 2-1 ratio pulley ). At 60HZ my motor turns at 1750 rpm and with the gear ratio I'm achieving 3500 rpm at the spindle. I want to run the motor at 120HZ so I can get 7000 rpm maximum *spindle rpm ( which is 3500 rpm on the motor )

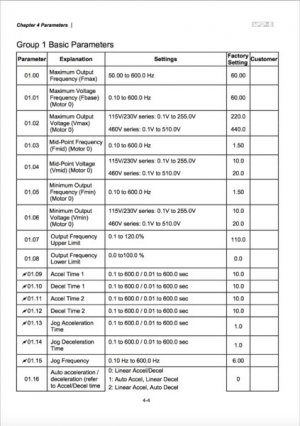

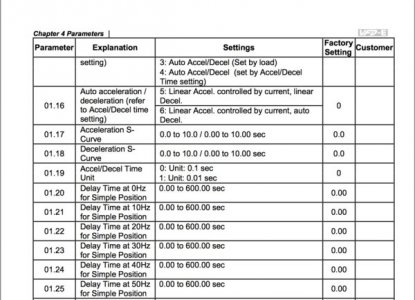

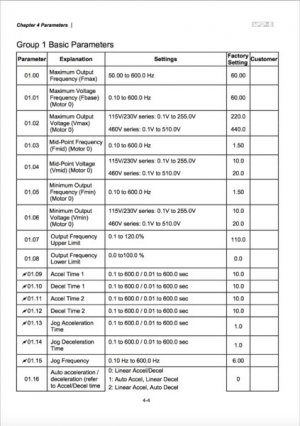

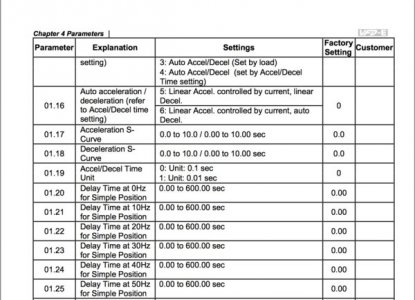

The VFD manual suggests I need to alter the mid point Frequency ( section 4-48 / parameter 01.01 ) . I'm not sure what to set it to. Also, when I attempted to set ( section 4-49 / parameter 01.05 ) to 2HZ the VFD error-ed and it auto set it back to the default 1.5HZ. The range is supposedly .1 HZ to 600HZ, so it must have some override if other settings aren't correct. I'm just not confident I can figure this puzzle out myself and hopeful someone experienced can lend a hand.

enclosed are pictures of the Motor's specifications and also the VFD manual settable parameters for tuning the motor.

And a link to the VFD manual is here :

http://www.delta.com.tw/product/em/.../manual/Delta_IA-MDS_VFD-E_UM_EN_20140912.pdf

Jake

I have a Delta VFD-E ( 230V ) and a Marathon Inverter motor ( this is a different motor than what came with the mill ). Its working "ok" with the original default settings ( that were for the original motor ) at 60HZ but I just replaced the spindle bearings in my mill so they can now handle 7000 rpm ( with my 2-1 ratio pulley ). At 60HZ my motor turns at 1750 rpm and with the gear ratio I'm achieving 3500 rpm at the spindle. I want to run the motor at 120HZ so I can get 7000 rpm maximum *spindle rpm ( which is 3500 rpm on the motor )

The VFD manual suggests I need to alter the mid point Frequency ( section 4-48 / parameter 01.01 ) . I'm not sure what to set it to. Also, when I attempted to set ( section 4-49 / parameter 01.05 ) to 2HZ the VFD error-ed and it auto set it back to the default 1.5HZ. The range is supposedly .1 HZ to 600HZ, so it must have some override if other settings aren't correct. I'm just not confident I can figure this puzzle out myself and hopeful someone experienced can lend a hand.

enclosed are pictures of the Motor's specifications and also the VFD manual settable parameters for tuning the motor.

And a link to the VFD manual is here :

http://www.delta.com.tw/product/em/.../manual/Delta_IA-MDS_VFD-E_UM_EN_20140912.pdf

Jake

Last edited: