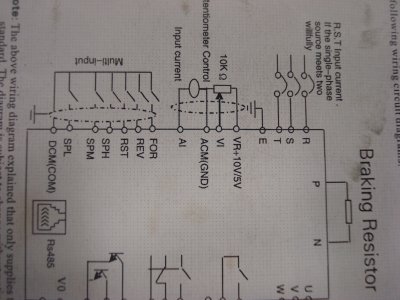

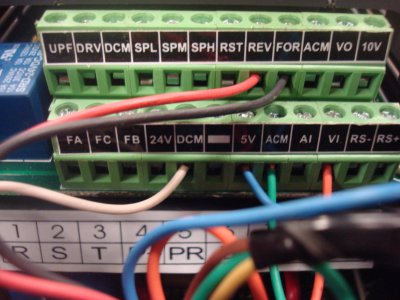

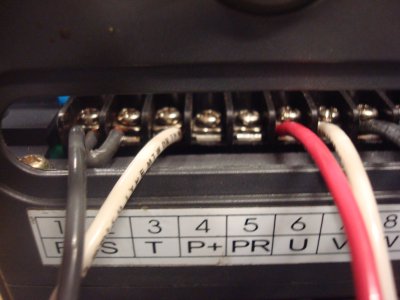

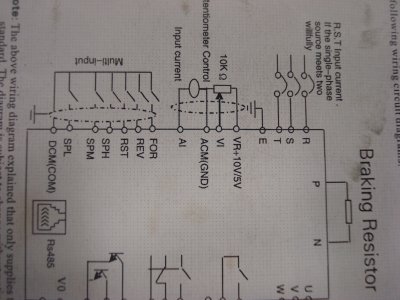

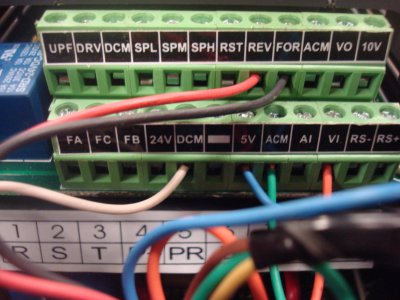

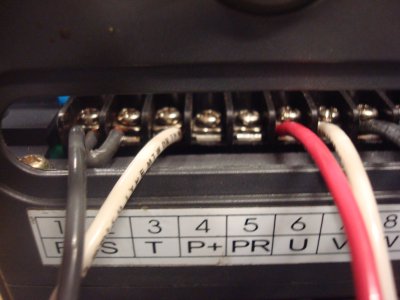

I'm trying to run my Sheldon lathe with a Huanyang vfd. My question pertains to wiring a remote pot to it. I have it working well with a remote f/r switch and e-stop button while controlling the frequency from the panel. I can't get the pot to work correctly though. I probably have it hooked up wrong or I'm missing a parameter, although I've been through them a few times. When I have it hooked up and the 003 parameter set to 1, I get some control with the pot, but it runs at real low frequency and the adjustment of the pot is limited. I bought the pot from Mcmaster-carr. It's a 10K pot. I would appreciate any suggestions. Here's some pics of the vfd and pot.

Chuck

Chuck