-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

VN #12 Stuck table

- Thread starter deker

- Start date

- Joined

- Jan 2, 2014

- Messages

- 8,853

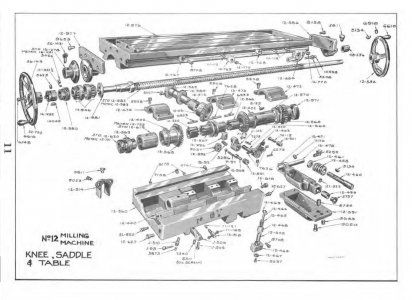

Pics like this aren't much use here - too small. PM me with your email & I'll send a copy of the entire manual.

Is it something you could put on the downloads section?

That would make it accessible to a wider audience.

Thanks,

-brino

- Joined

- Jan 2, 2016

- Messages

- 1,953

Have you tried turning the power back on, now that you have the feed lever free, then you the power feed to try moving the table back towards center?Cal,

I actually took the gib all the way out and still nothing. The X-axis leadscrew seems like it's what is wedged. I can rotate the feed driveshaft and that un-stuck the feed lever, but the leadscrew isn't going anywhere.

Thanks for the help.

Brino, I do believe the Download Section may prove to be the solution. VN12 Manual uploaded there. I did notice the existing version there - but this is a clearer version from a different source. I hope it helps!

- Joined

- Sep 3, 2011

- Messages

- 478

If it's actually bound up in the nut (12-619) and backlash adjustment collar (12-620), then I think your next step is to try to remove the table, leaving the leadscrew in place.So, a pin spanner was able to get the locking ring loosened, but the adjuster still isn't budging. Does somebody by chance have a parts explosion of the table to I can get a better idea what my options are at this point?

The drawing in post #11 is for the machines built after the 1952ish redesign of the No. 12 (which was apparently happening in conjunction with the development of the No. 12's replacement, the No. 16). If you have a 1952 table, great. You need to remove the right side handwheel bracket (12-586), etc., unbolt the table from the left side handwheel bracket (12-977) and slide it off to the right.

The pre-1952 table doesn't have removable left-side bracket. You have to disassemble the dial assembly and remove the bearing to disconnect the table from the leadscrew.

Which type of table do you have?

If it's actually bound up in the nut (12-619) and backlash adjustment collar (12-620), then I think your next step is to try to remove the table, leaving the leadscrew in place.

The drawing in post #11 is for the machines built after the 1952ish redesign of the No. 12 (which was apparently happening in conjunction with the development of the No. 12's replacement, the No. 16). If you have a 1952 table, great. You need to remove the right side handwheel bracket (12-586), etc., unbolt the table from the left side handwheel bracket (12-977) and slide it off to the right.

The pre-1952 table doesn't have removable left-side bracket. You have to disassemble the dial assembly and remove the bearing to disconnect the table from the leadscrew.

Which type of table do you have?

Cal,

I believe the machine is mid-40s vintage. Taking apart the dial assembly is no problem, but I'll need to figure out how to disassemble the bearing. It looks like there's a threaded brass/bronze collar inset into the table that needs a pin spanner. Does that sound about right? I'll try to get a picture or two shortly.

- Joined

- Sep 3, 2011

- Messages

- 478

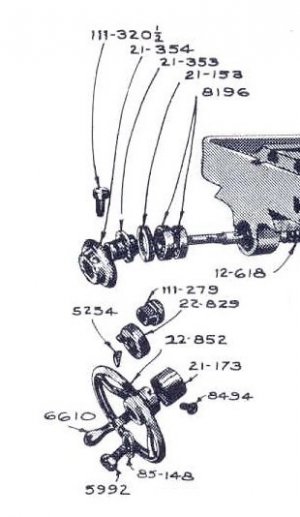

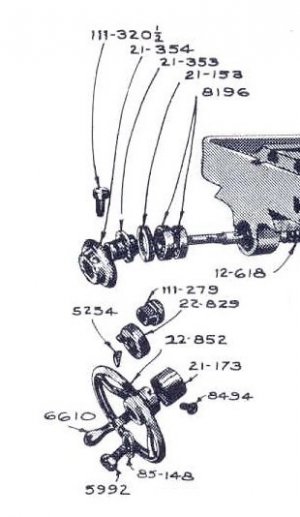

This is the table that you have:

The table feed screw has two sets of threads on the left end. The outer one mates with part 111-279, which is part of the mechanism that disengages the left handle for power feed operations. The inner threads mate with part 21-353, which is a sleeve that carries the graduated dial (21-354). This is what part 21-353 and the left end of the feed screw look like:

You can remove 21-353 with a pin-type face spanner.

Behind 21-353 is part 21-153, which is an externally threaded ring that sets the preload on the bearings (8196). I made up a custom spanner to remove it:

You don't need to remove the bearings to slide the table off of the feed screw. Once 21-153 is out, you should be able to slide the table off to the left. Make sure you support it with a shop hoist or something similar because it's VERY heavy.

Here's what the left end of the table and feed screw look like:

The table feed screw has two sets of threads on the left end. The outer one mates with part 111-279, which is part of the mechanism that disengages the left handle for power feed operations. The inner threads mate with part 21-353, which is a sleeve that carries the graduated dial (21-354). This is what part 21-353 and the left end of the feed screw look like:

You can remove 21-353 with a pin-type face spanner.

Behind 21-353 is part 21-153, which is an externally threaded ring that sets the preload on the bearings (8196). I made up a custom spanner to remove it:

You don't need to remove the bearings to slide the table off of the feed screw. Once 21-153 is out, you should be able to slide the table off to the left. Make sure you support it with a shop hoist or something similar because it's VERY heavy.

Here's what the left end of the table and feed screw look like:

The table is un-stuck! I had a spanner delivered over the weekend and when I went to start loosening the dial sleeve (21-353), the screw spun and freed up.

I did note that between the graduated dial and part 11-279 there is nothing on my mill, but there is a slot for a Woodruff key there. So, I'm guessing whatever mechanism is supposed to disengage the left hand wheel during power feed is AWOL (the left handle always spun under power feed and I just assumed that was correct).

I got the backlash adjusted and locked in, and the gib snugged up to something that "feels" reasonable. Is there a proper procedure for setting the gib adjustment?

The only thing left is to remove the feed box assembly since it appears that I may have lost one of the pins that lock in the u-joint at the rear of the drive shaft to the gearbox in all of this (or I assume so since the gearbox motor is turning, but the driveshaft isn't...). That looks relatively straightforward, but if there are any helpful tips and tricks for that I'm all ears.

Thanks again for all of your help Cal!

I did note that between the graduated dial and part 11-279 there is nothing on my mill, but there is a slot for a Woodruff key there. So, I'm guessing whatever mechanism is supposed to disengage the left hand wheel during power feed is AWOL (the left handle always spun under power feed and I just assumed that was correct).

I got the backlash adjusted and locked in, and the gib snugged up to something that "feels" reasonable. Is there a proper procedure for setting the gib adjustment?

The only thing left is to remove the feed box assembly since it appears that I may have lost one of the pins that lock in the u-joint at the rear of the drive shaft to the gearbox in all of this (or I assume so since the gearbox motor is turning, but the driveshaft isn't...). That looks relatively straightforward, but if there are any helpful tips and tricks for that I'm all ears.

Thanks again for all of your help Cal!

- Joined

- Sep 3, 2011

- Messages

- 478

The graduated dial (21-354) should ride on the outside of 21-353. 111-279 should be right next to 21-353. On my machine, 22-829 was stuck inside the 21-173, which is a simple tube that's pressed onto a step on the handwheel (22-852). The Woodruff key for 22-829 was sheared off and the mechanism didn't work.

We had to use an internal bearing puller to get 22-829 out of the sleeve:

You would think that there would be some sort of spring in between the the handwheel and the clutch, but the parts diagram doesn't show one. I don't think that the broached keyway is used on the No. 12. (The handwheel is borrowed from the No. 22 milling machine.)

Did you wind up removing the table?

It's a common mistake to adjust the gib so that the cranks feel nice, but that usually leaves them too loose. What I do is to set up a dial indicator on the knee, with the tip touching the table, then push/pull on the ends of the table until the indicator doesn't move when you apply force to the table. Try it with the table in the middle and at each end.

We had to use an internal bearing puller to get 22-829 out of the sleeve:

You would think that there would be some sort of spring in between the the handwheel and the clutch, but the parts diagram doesn't show one. I don't think that the broached keyway is used on the No. 12. (The handwheel is borrowed from the No. 22 milling machine.)

Did you wind up removing the table?

It's a common mistake to adjust the gib so that the cranks feel nice, but that usually leaves them too loose. What I do is to set up a dial indicator on the knee, with the tip touching the table, then push/pull on the ends of the table until the indicator doesn't move when you apply force to the table. Try it with the table in the middle and at each end.