- Joined

- Jan 18, 2017

- Messages

- 235

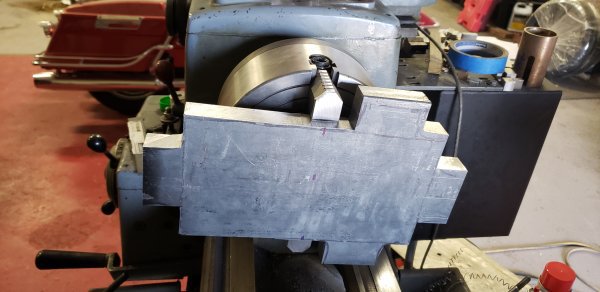

Moving the table under the dial indicator can give you an entirely wrong reading of flatness. The table may be sagging on both sides as it travels, and there will be no way to know it, the indicator will still show it as good, especially when cut and measured in the same machine and setup. Yes, a "surface plate" in proper calibration is needed to see if it is indeed flat and parallel.

I was concerned about that very thing. Not sure how I can test it with what I have other than a straight edge maybe. I'll see what I can figure out. I know its straighter, flatter than a dirt road!!!