-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Way Covers on a Lathe

- Thread starter ddickey

- Start date

- Joined

- Jul 8, 2018

- Messages

- 880

I was looking into cheap accordion covers to fit between the carriage and the headstock, but couldn't find any that were wide enough (X-wards).

- Joined

- Jul 8, 2018

- Messages

- 880

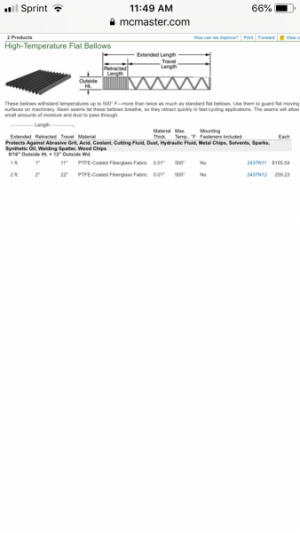

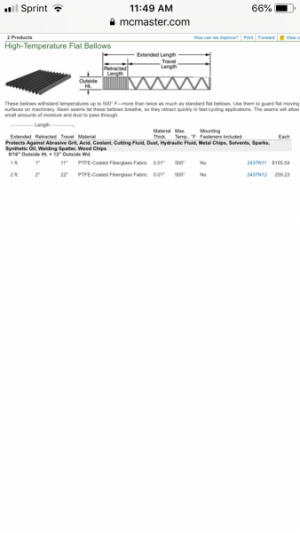

I use accordion covers on mine. I was fortunate that a machine at work needed new ones and these fit perfect. Lathe is a 14x40. McMaster Carr does sell them in larger sizes and they are pricey.

I have a 14x40. Do you know the measurements of that way cover? One of the problems searching for the cheap stuff is they list them by the external measurement, not the lathe size or the width of the ways they cover.

- Joined

- Jun 7, 2013

- Messages

- 10,086

I can't imagine that type of way cover holding up to blue chips.

- Joined

- Jan 31, 2016

- Messages

- 11,436

Not sure what the purpose of covering the ways would be for machining , but these guys in here at work totally destroyed the bed of a SB heavy 10 by polishing aluminum rollers with sandpaper over the years . I took that lathe out of here and put a Clausing Colchester 13" in its place . They better learn to cover the bed with pigmats before they go polishing or I'll lock the machine out . Case closed .

I can see covering the bed for toolpost grinding also .

I can see covering the bed for toolpost grinding also .

My reason for covering the ways is the most obvious reason. I hated making chips and having to constantly stop to wipe or remove the pile of chips that’s build up on the apron on chuck side. Then when you clean the cross slide and apron and chips fall all over the way. Then you gotta move the carriage to wipe the ways and not push any toward the carriage.

Now I don’t worry about any of that. I do occasionally lift the cover and check while giving the ways a nice bath of oil.

The best is I take a small paint brush and just run the pleats and all is clean. The material is like a rubbery plastic if that makes sense. Resist the oils and you’d have to get pretty hot to burn through the material.

This is the machine I pulled it off of which is a reel grinder. Throws sparks all day. I had to trim the cover to fit my application. The bellow is made of many plastic dividers let’s say. Then covered in the bellow material. The plastic dividers were cut to ride along the linear bearing rails originally. I had to cut off all the plastic underneath so the bellow was flat on the underside to slide on the ways of the lathe. I also cut the sides down so that it didn’t go over the leadscrew. My screw is already cover. The width of the cover is a touch over 11” and was 3” tall.

For my little 9x20 lathe I use a piece of rubber with a magnet at one end that sticks to carriage. Cover is about 6” long so it catches all the drops from the chuck and I just remove to clean off and reinstall. Works good but the accordion is better and protects more.

Now I don’t worry about any of that. I do occasionally lift the cover and check while giving the ways a nice bath of oil.

The best is I take a small paint brush and just run the pleats and all is clean. The material is like a rubbery plastic if that makes sense. Resist the oils and you’d have to get pretty hot to burn through the material.

This is the machine I pulled it off of which is a reel grinder. Throws sparks all day. I had to trim the cover to fit my application. The bellow is made of many plastic dividers let’s say. Then covered in the bellow material. The plastic dividers were cut to ride along the linear bearing rails originally. I had to cut off all the plastic underneath so the bellow was flat on the underside to slide on the ways of the lathe. I also cut the sides down so that it didn’t go over the leadscrew. My screw is already cover. The width of the cover is a touch over 11” and was 3” tall.

For my little 9x20 lathe I use a piece of rubber with a magnet at one end that sticks to carriage. Cover is about 6” long so it catches all the drops from the chuck and I just remove to clean off and reinstall. Works good but the accordion is better and protects more.

- Joined

- Jun 7, 2013

- Messages

- 10,086

Most mills do not make the blue chips that I see coming off my lathe, thick and wide and smoking hot; blue is 600 deg.+F.I used to install those same covers in Mills, they hold up quite well.

Not being flat and usually a layer of chips already in the pleats helps with heat disbursement. Haven’t had any problems not even melted into the material. I do not do production work so could be different. I checked McMaster they have a standard bellow good to 300* resist oils and grinding grit. They also have a high temp bellow that is good to 500* with all the other protection for a little more price.