Purchased this unit used off from Facebook Marketplace. Story was that it was purchased but never used. Seemed to still have the shipping grease on it.

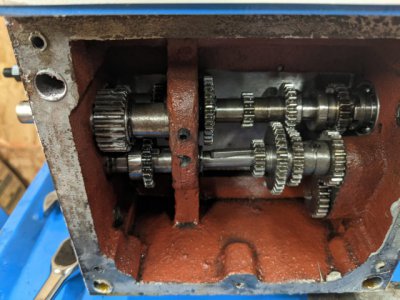

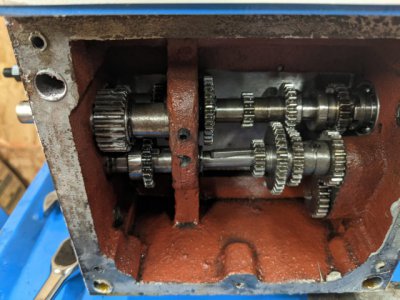

Really excited i set it up and started to clean and oil it. That went well until i attempted to use it for a test cut. I made a few cuts and then ran the carriage into the chip shield in the back. This twisted the lower shaft inside of the gearbox.

Where can i find a replacement shaft? I have tried the following:

Thanks,

-Levi

Really excited i set it up and started to clean and oil it. That went well until i attempted to use it for a test cut. I made a few cuts and then ran the carriage into the chip shield in the back. This twisted the lower shaft inside of the gearbox.

Where can i find a replacement shaft? I have tried the following:

- Precision Matthews - they don't sell parts to machines they don't sell. Looks the same as the 1127 they sell but they said it's not exactly the same.

- DROPROS - they don't do much with Weiss b/c of price increases; the parts guy is looking into it but likely wouldn't be able to help much

- Emailed Weiss direct; given the time zone difference it'll likely be tomorrow morning.

Thanks,

-Levi