- Joined

- Nov 21, 2021

- Messages

- 35

What change gears are needed to cut metric threads on an imperial lathe or imperial threads on a metric lathe.

This is probably the most common question involving the gear train. I have just completed a major update of RideTheGearTrain.com to help address this question. The only change that a user will see is a new option in Step 5B where you can run the program with more than one pitch or TPI. (try clicking the blue links.) The older method was to ask the user to enter a range of values from a low value, to a high value at fixed intervals. The problem with that is that the pitches in the M-metric series or BA etc are not equally spaced. So the new option is for the user to enter a LIST of pitches or TPI.

Efficiency Improvement:

Originally, if the user requested 25 values (eg the M-series of metric pitches), the program would run 25 times. Going through every possible gear train setup (and gearbox settings) requiring huge numbers of calculations and the program would take so much time that the server would kill it (time-out error). SO, the new version only goes through all the gear and gearbox settings once. With each setup it calculates the thread produced and then compares it with the list of required pitch or TPI values to see whether any of them are within the acceptable error. If so they are added to a results array. At the end the array is sorted and displayed. That required some major changes, but it is very useful.

How to enter a list of pitches or TPI:

Very simple really. Go through steps 1-4 to set up your lathe. In step 3 choose either imperial thread with TPI or metric thread with mm pitch. Choose Step 5B and click the radio button marked LIST. Type in a list of pitches or TPI you want to run. Then return to menu and RUN (step 6). However, instead of typing all the numbers yourself, the instructions display lists for standard threads: UNC/UNF/BSW, another for BA, and for the metric M-series etc. You can copy and paste these lists into the INPUT box to save you typing. You may choose a smaller set by just using part of the list.

HELP:

The help file now contains over 11,000 lines of text, photos and video links. There is a HELP button in the main menu. If you click that you can search the help file. Also each page of the program has several help buttons to take you directly to relevant chapters in the help file, so you don't have to read the whole lot! I will include some links to useful chapters below:

METRIC IMPERIAL TRANSPOSING GEARS

These are the compound gears that can be used to convert between metric and imperial. Keep in mind however, that you can often produce certain metric threads without using these special gears. Run RideTheGearTrain with a single pitch or TPI in Step 5A to find out whether you can produce the required thread.

The standard gear for conversion has 127 teeth and this is used because 2 x 127 =254 and the required conversion factor is 25.4 so this can give perfect conversions with 0% error. It can be combined with any other gear eg 100 to make 127/100, 127/120, 120/135 provided that you have other gears to compensate for these changes.

However if you are willing to accept small errors you can use other gear combinations. There it a special item on the menu called Metric-Imperial Conversion Gears. This does not require specific information about your lathe. You simply enter the gear ratio you require (in this case 1.27) and it lists the pairs of gears that will produce this ratio. It is quite surprising how many options are available. Click the blue help button under the heading. It is called Conversion Gears.

ADAPTER:

You may be able to use gears that you already have to make the conversion. More modern lathes allow you to use the change gears to make up compound pairs without connecting them permanently. Older lathes such as Boxford lathes which are South Bend clones, require an adapter to do this. Photos and drawings of the adapter are shown here in the help file and there are yellow HELP buttons in the program.

With this feature you can select Automatic Compound Gears when designing the gear train in Step 2A. If you select a gear train with one compound pair (2 gears joined together), combined with a stud gear and leadscrew gear that can be changed, you have 4 gears in the train. If you have 6 gear wheels to choose from the number of combinations the computer program tries automatically is 6 x 5 x 4 x 3 =360 and if you have a gearbox with 40 lever position you multiply that by 40 giving 14,400 combinations. If you had 10 gears to choose from there would be 10 x 9 x 8 x 7 = 5040 combinations x40 with a gearbox gives 201,600 possibilities. So there are a lot of possibilities. If you are really keen you can add a second pair of compound gears (which may require a second adapter) with 6 gears in the train and if you have 10 gears to choose from the number of calculations increases to 10 x 9 x 8 x 7 x 6 x 5 = 151,200 and with a gearbox x40 gives 6 million combinations. It is quite likely that you don't need a special metric conversion set.

ADJUSTING THE NUMBER OF RESULTS YOU GET

You may find that you get either too many or too few results. In that case you can make alterations and run the program again.

Increasing the acceptable error in Step 4 increases the number of results, and decreasing the error reduces the number of results.

Altering the geartrain design in Step 2A makes a big difference, as illustrated by the calculations above. It may be best to start with "No Compound Gears" with say 2% error, because this is the simplest to set up, but produces the fewest possible combinations. If this does not provide your answer try "One Compound Gear" without Automatic compound gears turned on. If you have an adapter or have a more modern lathe that does not require an adaper turn on Automatic Compound gears. This gives a lot more possibilities. Finally, you could try "Two Compound Gears" but this is much more complex to set up.

EXPERIMENTING WITH NEW GEARS

If you are unable to produce the threads you want, you can start experimenting by adding extra gears to your set of change gears. That way you can decide what new gear you might need to make or buy. Keep in mind that 3D printed plastic and composite gears are now readily available (as mentioned in previous posts).

One thing you might consider is a 127 tooth gear or an approximation such as the common 63/80 conversion set. But notice that 63 divided by 3 is 21, so a 21 tooth gears combined with other gears that can multiply by 3 may solve your problem, and another gear you could try is 21 x 2 = 42 teeth. So just try everything!

I have made video tutorials about how to use the program and they are shown at the bottom of the menu. But it is easy enough just to follow the Quick Start guide at the top of the menu. The process has been divided into several steps to make it easier to make changes after you have completed the first run. If you need more help or want your lathe added to the list, please don't hesitate to contact me.

Evan

This is probably the most common question involving the gear train. I have just completed a major update of RideTheGearTrain.com to help address this question. The only change that a user will see is a new option in Step 5B where you can run the program with more than one pitch or TPI. (try clicking the blue links.) The older method was to ask the user to enter a range of values from a low value, to a high value at fixed intervals. The problem with that is that the pitches in the M-metric series or BA etc are not equally spaced. So the new option is for the user to enter a LIST of pitches or TPI.

Efficiency Improvement:

Originally, if the user requested 25 values (eg the M-series of metric pitches), the program would run 25 times. Going through every possible gear train setup (and gearbox settings) requiring huge numbers of calculations and the program would take so much time that the server would kill it (time-out error). SO, the new version only goes through all the gear and gearbox settings once. With each setup it calculates the thread produced and then compares it with the list of required pitch or TPI values to see whether any of them are within the acceptable error. If so they are added to a results array. At the end the array is sorted and displayed. That required some major changes, but it is very useful.

How to enter a list of pitches or TPI:

Very simple really. Go through steps 1-4 to set up your lathe. In step 3 choose either imperial thread with TPI or metric thread with mm pitch. Choose Step 5B and click the radio button marked LIST. Type in a list of pitches or TPI you want to run. Then return to menu and RUN (step 6). However, instead of typing all the numbers yourself, the instructions display lists for standard threads: UNC/UNF/BSW, another for BA, and for the metric M-series etc. You can copy and paste these lists into the INPUT box to save you typing. You may choose a smaller set by just using part of the list.

HELP:

The help file now contains over 11,000 lines of text, photos and video links. There is a HELP button in the main menu. If you click that you can search the help file. Also each page of the program has several help buttons to take you directly to relevant chapters in the help file, so you don't have to read the whole lot! I will include some links to useful chapters below:

METRIC IMPERIAL TRANSPOSING GEARS

These are the compound gears that can be used to convert between metric and imperial. Keep in mind however, that you can often produce certain metric threads without using these special gears. Run RideTheGearTrain with a single pitch or TPI in Step 5A to find out whether you can produce the required thread.

The standard gear for conversion has 127 teeth and this is used because 2 x 127 =254 and the required conversion factor is 25.4 so this can give perfect conversions with 0% error. It can be combined with any other gear eg 100 to make 127/100, 127/120, 120/135 provided that you have other gears to compensate for these changes.

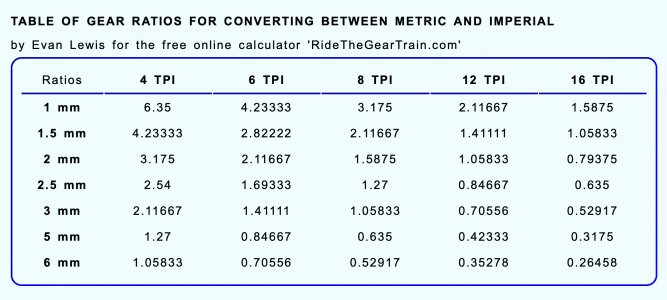

However if you are willing to accept small errors you can use other gear combinations. There it a special item on the menu called Metric-Imperial Conversion Gears. This does not require specific information about your lathe. You simply enter the gear ratio you require (in this case 1.27) and it lists the pairs of gears that will produce this ratio. It is quite surprising how many options are available. Click the blue help button under the heading. It is called Conversion Gears.

ADAPTER:

You may be able to use gears that you already have to make the conversion. More modern lathes allow you to use the change gears to make up compound pairs without connecting them permanently. Older lathes such as Boxford lathes which are South Bend clones, require an adapter to do this. Photos and drawings of the adapter are shown here in the help file and there are yellow HELP buttons in the program.

With this feature you can select Automatic Compound Gears when designing the gear train in Step 2A. If you select a gear train with one compound pair (2 gears joined together), combined with a stud gear and leadscrew gear that can be changed, you have 4 gears in the train. If you have 6 gear wheels to choose from the number of combinations the computer program tries automatically is 6 x 5 x 4 x 3 =360 and if you have a gearbox with 40 lever position you multiply that by 40 giving 14,400 combinations. If you had 10 gears to choose from there would be 10 x 9 x 8 x 7 = 5040 combinations x40 with a gearbox gives 201,600 possibilities. So there are a lot of possibilities. If you are really keen you can add a second pair of compound gears (which may require a second adapter) with 6 gears in the train and if you have 10 gears to choose from the number of calculations increases to 10 x 9 x 8 x 7 x 6 x 5 = 151,200 and with a gearbox x40 gives 6 million combinations. It is quite likely that you don't need a special metric conversion set.

ADJUSTING THE NUMBER OF RESULTS YOU GET

You may find that you get either too many or too few results. In that case you can make alterations and run the program again.

Increasing the acceptable error in Step 4 increases the number of results, and decreasing the error reduces the number of results.

Altering the geartrain design in Step 2A makes a big difference, as illustrated by the calculations above. It may be best to start with "No Compound Gears" with say 2% error, because this is the simplest to set up, but produces the fewest possible combinations. If this does not provide your answer try "One Compound Gear" without Automatic compound gears turned on. If you have an adapter or have a more modern lathe that does not require an adaper turn on Automatic Compound gears. This gives a lot more possibilities. Finally, you could try "Two Compound Gears" but this is much more complex to set up.

EXPERIMENTING WITH NEW GEARS

If you are unable to produce the threads you want, you can start experimenting by adding extra gears to your set of change gears. That way you can decide what new gear you might need to make or buy. Keep in mind that 3D printed plastic and composite gears are now readily available (as mentioned in previous posts).

One thing you might consider is a 127 tooth gear or an approximation such as the common 63/80 conversion set. But notice that 63 divided by 3 is 21, so a 21 tooth gears combined with other gears that can multiply by 3 may solve your problem, and another gear you could try is 21 x 2 = 42 teeth. So just try everything!

I have made video tutorials about how to use the program and they are shown at the bottom of the menu. But it is easy enough just to follow the Quick Start guide at the top of the menu. The process has been divided into several steps to make it easier to make changes after you have completed the first run. If you need more help or want your lathe added to the list, please don't hesitate to contact me.

Evan