- Joined

- May 3, 2020

- Messages

- 229

When cutting threads, how much error can be tolerated? I'm thinking in terms of % error on TPI, comparing calculated value to nominal.

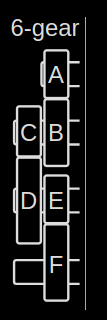

I need to cut an M39x4 thread, which is not on the chart for my lathe (Harbor Freight 9x20). I counted some teeth, looked inside the 9-position gearbox, and eventually made a spreadsheet. Simple, right? Well, the TPI numbers did not match the documentation on the lathe. So I chased my tail for a while. After trying and text books had failed, I decided to look at a calculator. Turns out, I was right all along and there's just a lot of error. http://www.spokecalculator.net/other/cgc/

The whole point of this exercise is to be able to move the chuck between the lathe and mill without taking the part out. I've already cut flats on the chuck's backplate, which is convenient for mounting the chuck in the mill's vise. It adds up in Z distance but so far, so good. Now I'd like to extend that flexibility to the rotary table.

While you're here, do you think an MT2-M39x4 adapter will work for holding a 6-jaw chuck onto a rotary table? It's the 6" Grizzly H7527. If it's set up in the normal way, rational axis parallel to Z, I think it would be OK. Set up on its side, I'm less sure about. Normally the M39x4 has a thread, land, and shoulder. The thread secures the chuck against the shoulder and the land provides concentricity. If the rotary table surface IS THE SHOULDER, could it be rigid enough for light milling?

I need to cut an M39x4 thread, which is not on the chart for my lathe (Harbor Freight 9x20). I counted some teeth, looked inside the 9-position gearbox, and eventually made a spreadsheet. Simple, right? Well, the TPI numbers did not match the documentation on the lathe. So I chased my tail for a while. After trying and text books had failed, I decided to look at a calculator. Turns out, I was right all along and there's just a lot of error. http://www.spokecalculator.net/other/cgc/

The whole point of this exercise is to be able to move the chuck between the lathe and mill without taking the part out. I've already cut flats on the chuck's backplate, which is convenient for mounting the chuck in the mill's vise. It adds up in Z distance but so far, so good. Now I'd like to extend that flexibility to the rotary table.

While you're here, do you think an MT2-M39x4 adapter will work for holding a 6-jaw chuck onto a rotary table? It's the 6" Grizzly H7527. If it's set up in the normal way, rational axis parallel to Z, I think it would be OK. Set up on its side, I'm less sure about. Normally the M39x4 has a thread, land, and shoulder. The thread secures the chuck against the shoulder and the land provides concentricity. If the rotary table surface IS THE SHOULDER, could it be rigid enough for light milling?