- Joined

- Sep 22, 2010

- Messages

- 7,223

Hey Guys,

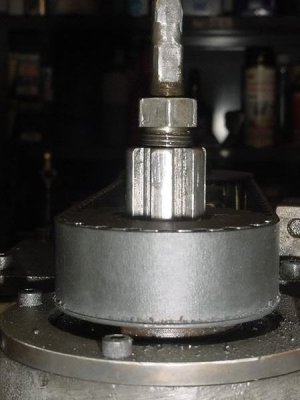

On a Bridgeport-type mill, is it "proper" to remove the collet by loosening the drawbar slightly and then giving the drawbar a good wallop to release the taper, or will that cause damage to the spindle?

If not, what is the "proper way" for doing it?

In the Darrell Holland video on mills, he locks the quill, holds the drive lock, loosens the draw bar and just gives the drawbar nut a good wack.

is there a way around hitting it, like using a drawbar that is captive with a left-hand nut so that, as you loosen the drawbar, it comes up against the nut and can't go any further, forcing the collet down?

Opinions please?

Thanks,

Nelson

On a Bridgeport-type mill, is it "proper" to remove the collet by loosening the drawbar slightly and then giving the drawbar a good wallop to release the taper, or will that cause damage to the spindle?

If not, what is the "proper way" for doing it?

In the Darrell Holland video on mills, he locks the quill, holds the drive lock, loosens the draw bar and just gives the drawbar nut a good wack.

is there a way around hitting it, like using a drawbar that is captive with a left-hand nut so that, as you loosen the drawbar, it comes up against the nut and can't go any further, forcing the collet down?

Opinions please?

Thanks,

Nelson