-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

"What Is This Thing?" Running Thread

- Thread starter intjonmiller

- Start date

- Joined

- Apr 21, 2015

- Messages

- 894

Good questions. Honestly I haven't spent any more time with it than maybe 30 seconds looking at it, unscrewing it, and taking those pictures. I'll look closer next time I'm in the shop.

- Joined

- Apr 21, 2015

- Messages

- 894

So I think that thing may be used for metal engraving. Not sure, but it looks a lot like a tool in an engraving video I came across on YouTube the other day. I had never seen that done before, so I had no idea what the tools looked like. Next time I come across that thing in the shop I'll see if it cuts the way I suspect it will.

Today I'm wondering about two other tools. Both I more or less "get", but would like to nail down more specifically if we can.

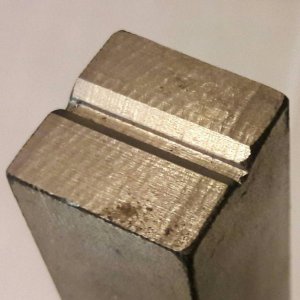

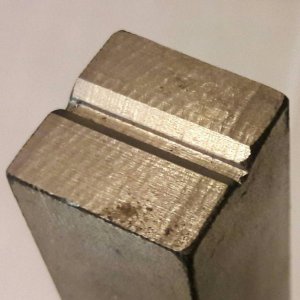

First up, this form tool came in a box of stuff with the mill.

Three brazed carbide teeth ground to the same profile. Guide bearing makes me think it would be for a woodworking router, but the fact that it was with end mills and a t-nut hold down kit and a vertical mill makes me wonder. Obviously no one will mill metal handheld more than once (other than the occasional light duty aluminum and brass stuff with woodworking tools, as I've done). Is there a use for a guide bearing like that on a machining tool? Seems like a clumsy way of controlling depth of cut to me.

The profile it cuts is probably fairly obvious, but I tried it on the end of a piece of 1" square stock CRS and it easily cut this nice v with relief. This is the full depth of cut that the guide bearing allows.

Regardless of what it was originally for I will certainly use it for the Vs on the copper jaws of the kant twist clamps I'm going to finish making one of these days. Any idea what else it would be used for?

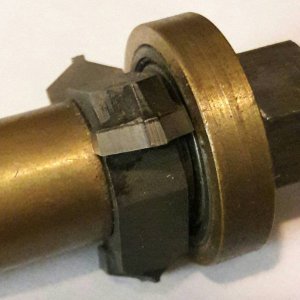

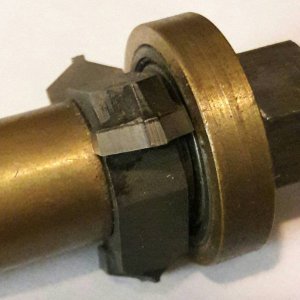

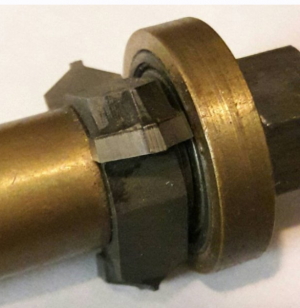

Finally I assume this is some sort of arbor. It was still in the original, sealed bag. I cleaned the oil off of it for this photo. It has a gorgeous crosshatch grind that my cell phone camera doesn't do justice.

Obviously it's R8, with both ends threaded, but I'm not personally familiar with this configuration. 1" OD on the end. I'm sure it's quite obvious to those who have dealt with more tooling than I have, but I'm not sure how this style is used. I'm sure a link would suffice for explaining this one.

Thanks!

Today I'm wondering about two other tools. Both I more or less "get", but would like to nail down more specifically if we can.

First up, this form tool came in a box of stuff with the mill.

Three brazed carbide teeth ground to the same profile. Guide bearing makes me think it would be for a woodworking router, but the fact that it was with end mills and a t-nut hold down kit and a vertical mill makes me wonder. Obviously no one will mill metal handheld more than once (other than the occasional light duty aluminum and brass stuff with woodworking tools, as I've done). Is there a use for a guide bearing like that on a machining tool? Seems like a clumsy way of controlling depth of cut to me.

The profile it cuts is probably fairly obvious, but I tried it on the end of a piece of 1" square stock CRS and it easily cut this nice v with relief. This is the full depth of cut that the guide bearing allows.

Regardless of what it was originally for I will certainly use it for the Vs on the copper jaws of the kant twist clamps I'm going to finish making one of these days. Any idea what else it would be used for?

Finally I assume this is some sort of arbor. It was still in the original, sealed bag. I cleaned the oil off of it for this photo. It has a gorgeous crosshatch grind that my cell phone camera doesn't do justice.

Obviously it's R8, with both ends threaded, but I'm not personally familiar with this configuration. 1" OD on the end. I'm sure it's quite obvious to those who have dealt with more tooling than I have, but I'm not sure how this style is used. I'm sure a link would suffice for explaining this one.

Thanks!

- Joined

- Nov 27, 2012

- Messages

- 7,858

Looks like a shell mill arbor. It allows you to bolt on a shell mill endmill (large endmill) or a shell face mill cutter.

Come to think of it, my PM45M came with one, sitting in a box somewhere.

Come to think of it, my PM45M came with one, sitting in a box somewhere.

- Joined

- May 4, 2015

- Messages

- 3,583

I think that gouge is for cutting printing blocks of linoleum.

- Joined

- Apr 21, 2015

- Messages

- 894

Still wondering about that form tool, but today we have a new challenge: Name That Collet! This guy (Frederik Moberg on YouTube) has a really cool lathe that came with MASSIVE collets, but he doesn't know what kind they are in order to locate a few more. Please click through to view this on YouTube and tell him what he has if you recognize it. All anyone has identified so far is that they are in the category of segmented collets.

- Joined

- Jan 2, 2014

- Messages

- 8,852

First up, this form tool came in a box of stuff with the mill.

Jon, when I first saw that one I thought it was a chamfering tool for use in a vertical mill, using the bearing to locate it in the hole.

Of course that doesn't explain why it's also sharpened on the other edge.....if you flip it over it would be running backwards!

Maybe could be used for "back chamfering" thru a hole if the bearing was on the other side......

-brino

- Joined

- Mar 19, 2017

- Messages

- 308

I think it is a mill table bump stop that will flipI'll start.

This was in the box of change and reversing gears, tooling, and random workpieces and offcuts that came with my father's Logan 850 lathe. Any idea what I is? It appears to me to have been cut off of something else, as there is a rough end and no apparent mount point. Not sure if it's worth keeping.

View attachment 217828

View attachment 217829

View attachment 217830

View attachment 217831

Out of the way . Then flip it back down to bump

Stop a part .

You have a post and the base missing

Just make you a post that will fit that hole and a base plate with a hole in it for the post . With a clap or set screw . You will need a hole through the plate to run you bolt into you T- nut in the table slot.

Make the plate out of a piece of 3/4 x 2" x 4"

There you have it

- Joined

- Mar 19, 2017

- Messages

- 308

Looks like it could be for cutting holes in leatherOr maybe for leather work?

Belts for the lathe