- Joined

- Feb 8, 2021

- Messages

- 15

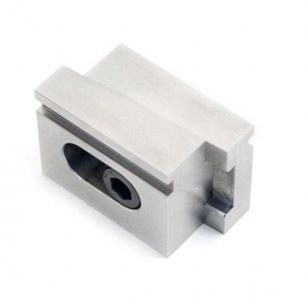

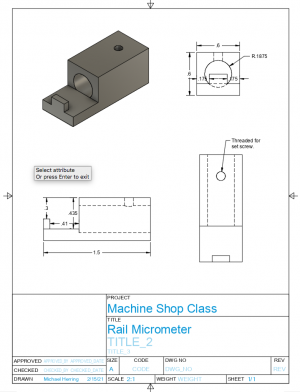

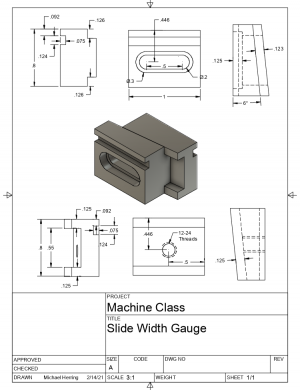

I'm looking to get some feedback on what kind of steel I should choose for a couple of small mill projects I have chosen for an upcoming machine shop class. I was looking at 1018 steel and O1 tool steel but I'm open to suggestions. These are both gauges for measuring 1911 slides and frames. Please see the attached pics. Any feedback is appreciated.