-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What TPI does a micrometer use

- Thread starter tim81

- Start date

https://en.m.wikipedia.org/wiki/Differential_screw very interesting as a project

- Joined

- Jun 7, 2013

- Messages

- 10,135

A 40 thread micrometer head would be easily damaged with any jam up on a lathe, I have a lathe stop on my 19" lathe that is made like a micrometer head, made by Monarch, that uses a 20 TPI thread that is much stronger than the 40 TPI; the thimble is about twice the diameter of the mike thimble so there is plenty of room for the thousandth graduations.

- Joined

- Dec 18, 2019

- Messages

- 6,525

My favorite is

I made a differential screw for a tail stock adjuster. Used a M6x1 and a M5x0.8, so 0.2mm/turn for the fine adjust and 1mm/turn for the coarse adjust. Turned out I needed to use an M5 to make it fit, and because I couldn't find a M6x0.8 tap. That size is a bit too small for me to single point at my current skill level.

I made a differential screw for a tail stock adjuster. Used a M6x1 and a M5x0.8, so 0.2mm/turn for the fine adjust and 1mm/turn for the coarse adjust. Turned out I needed to use an M5 to make it fit, and because I couldn't find a M6x0.8 tap. That size is a bit too small for me to single point at my current skill level.

Can you share any pic of. It sure is a very cool tool to have around.My favorite is

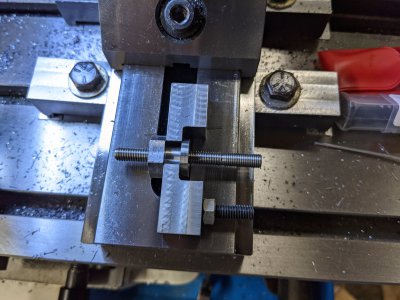

View attachment 467467

I made a differential screw for a tail stock adjuster. Used a M6x1 and a M5x0.8, so 0.2mm/turn for the fine adjust and 1mm/turn for the coarse adjust. Turned out I needed to use an M5 to make it fit, and because I couldn't find a M6x0.8 tap. That size is a bit too small for me to single point at my current skill level.

- Joined

- Dec 18, 2019

- Messages

- 6,525

Can you share any pic of. It sure is a very cool tool to have around.

Spinning the captive nut, while holding the brass knob is the coarse adjust. The captive nut is M6x1. Turning the knob and holding the nut is the fine adjust, with 0.2mm/turn. It goes backward from what I expected, but it does work. For some reason I needed some shims to get it to work, so I left them in place, otherwise it was a little tight to turn. The captive nut rests in a u channel. Don't know how I came up with the inspiration, but it just came to me. The first picture shows the custom nut I made to slide in the slot. This way I can set the lock from the top side of the tail stock instead of the bottom side. The second picture shows the original configuration. Mini-lathes sure do take a lot of liberties, and make easy adjustments hard...

Thank you so much man, it’s a beauty and very very useful tool. It’s perfect for alignment.View attachment 467504View attachment 467505View attachment 467508View attachment 467511View attachment 467516

Spinning the captive nut, while holding the brass knob is the coarse adjust. The captive nut is M6x1. Turning the knob and holding the nut is the fine adjust, with 0.2mm/turn. It goes backward from what I expected, but it does work. For some reason I needed some shims to get it to work, so I left them in place, otherwise it was a little tight to turn. The captive nut rests in a u channel. Don't know how I came up with the inspiration, but it just came to me. The first picture shows the custom nut I made to slide in the slot. This way I can set the lock from the top side of the tail stock instead of the bottom side. The second picture shows the original configuration. Mini-lathes sure do take a lot of liberties, and make easy adjustments hard...