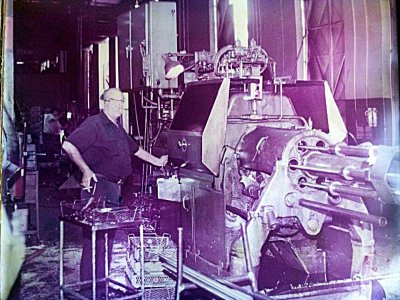

My cousin sent this photo to me on FaceBook the other day. Her grandfather was my uncle Cleo Cassidy working in Los Angeles, California back in the 1960's to 1980's. I think it is a screw machine but from the angle I am not sure. It is an old photo that I cleaned up so it would be easier to see. I appreciate your comments.

Thanks everyone, Bill

Thanks everyone, Bill