- Joined

- Nov 24, 2013

- Messages

- 257

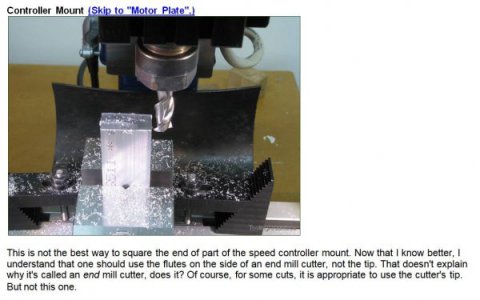

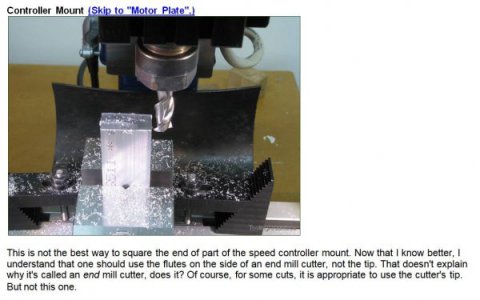

The attached picture indicates a cut using an endmill and it says it should not have been done this way but I don’t understand why. Picture is taken from https://toolingaround.ca/lms.php

The text on the picture also says “..for some cuts, it is appropriate…” What are these appropriate cuts?

Thank you

Nicolas

The text on the picture also says “..for some cuts, it is appropriate…” What are these appropriate cuts?

Thank you

Nicolas