- Joined

- Jan 27, 2018

- Messages

- 43

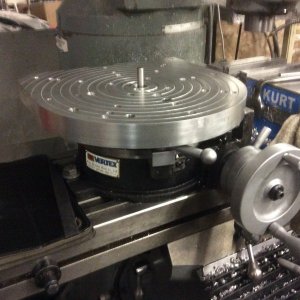

Hello I am new to machining, I got into machining to make folding knives. I am currently in the process of making my first one and just got a mill and have been slowly buying accessories for the mill, I swear I've spent more on the tooling and accessories for the mill than I did for the actual mill itself. Anyways I bought a piece of half inch thick aluminum plate to go on top of my rotary table to act as a fixture/sacrificial waste board. I want to flatten it and as far as I can tell the best way is with a surfacing bit, Not sure if that's what they are actually called. Anyways I have 100-150$ hoping that gets me a decent solution, Would prefer any ebay links or what exactly I should be looking for (certain brands or types) I just need to make an 8"x8" piece of aluminum flat.

Thank you

Thank you