- Joined

- Jun 15, 2017

- Messages

- 525

I bought a Gorton 375 grinder, and then I failed to do anything with it other than putting a mobile base on it and getting the bearings cleaned up. Now I would like to start using it to sharpen drills.

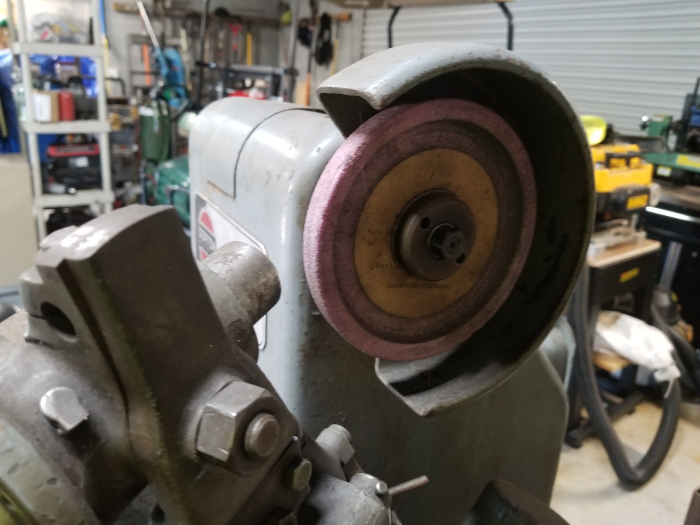

I'm attaching a photo of the wheel it came with. I have no idea whether this is a good wheel for drills. I'm not sure if the wheel originally looked like this, either. I don't know whether it was always this shape or the cup part is just gone.

What's a good wheel for this thing? Does anyone make CBN wheels for it? I like CBN.

I'm attaching a photo of the wheel it came with. I have no idea whether this is a good wheel for drills. I'm not sure if the wheel originally looked like this, either. I don't know whether it was always this shape or the cup part is just gone.

What's a good wheel for this thing? Does anyone make CBN wheels for it? I like CBN.