- Joined

- Jan 20, 2016

- Messages

- 602

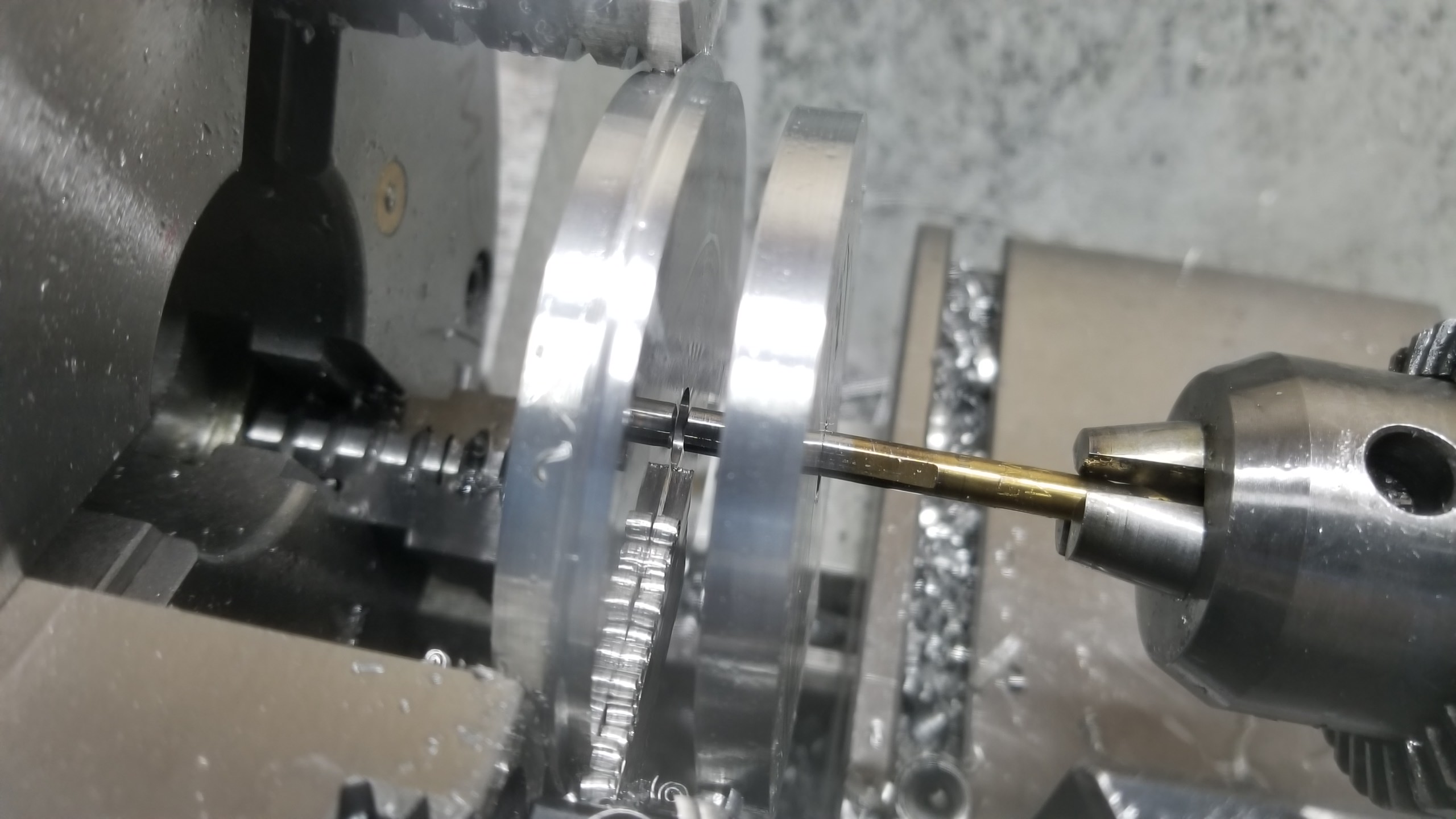

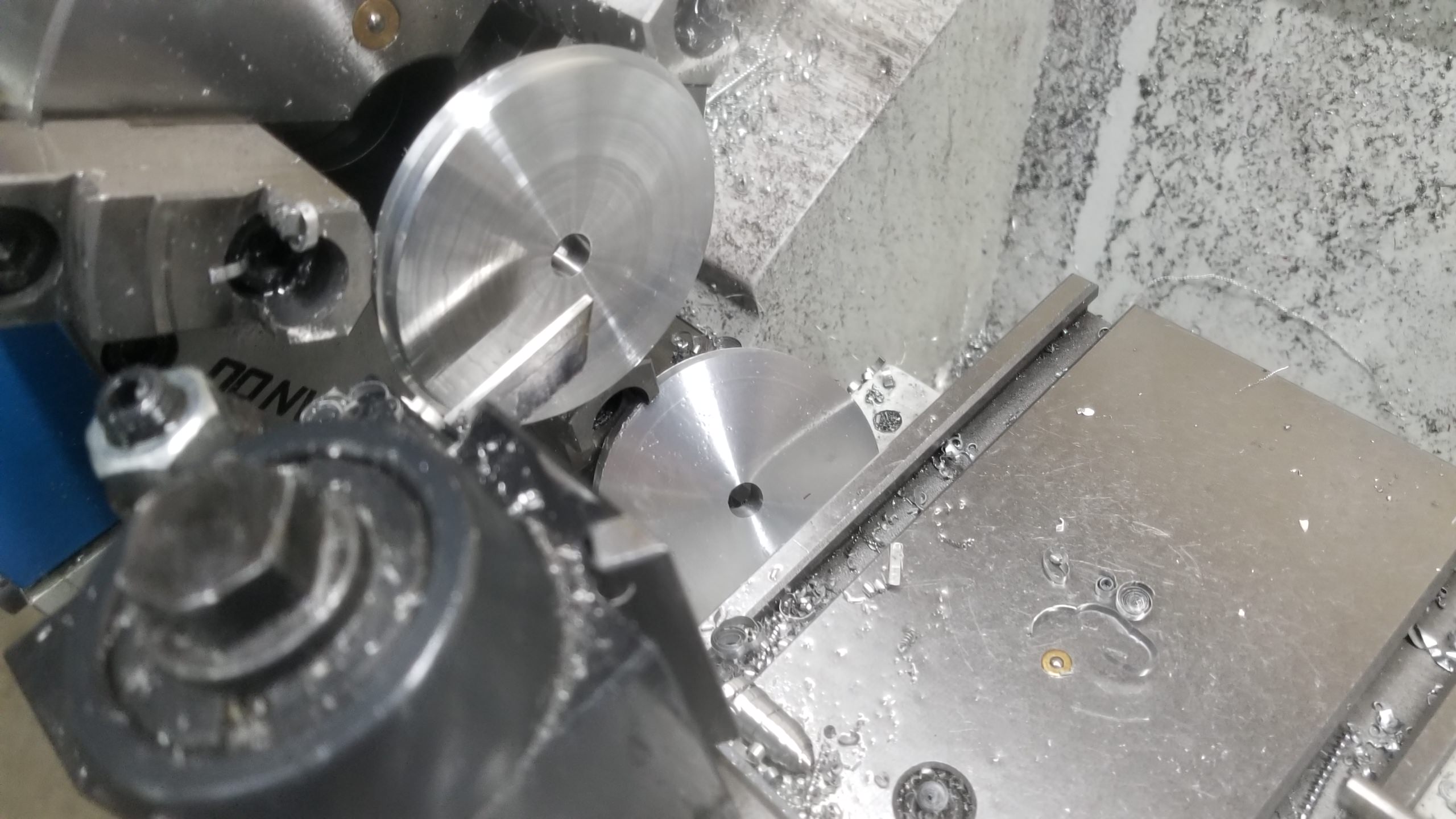

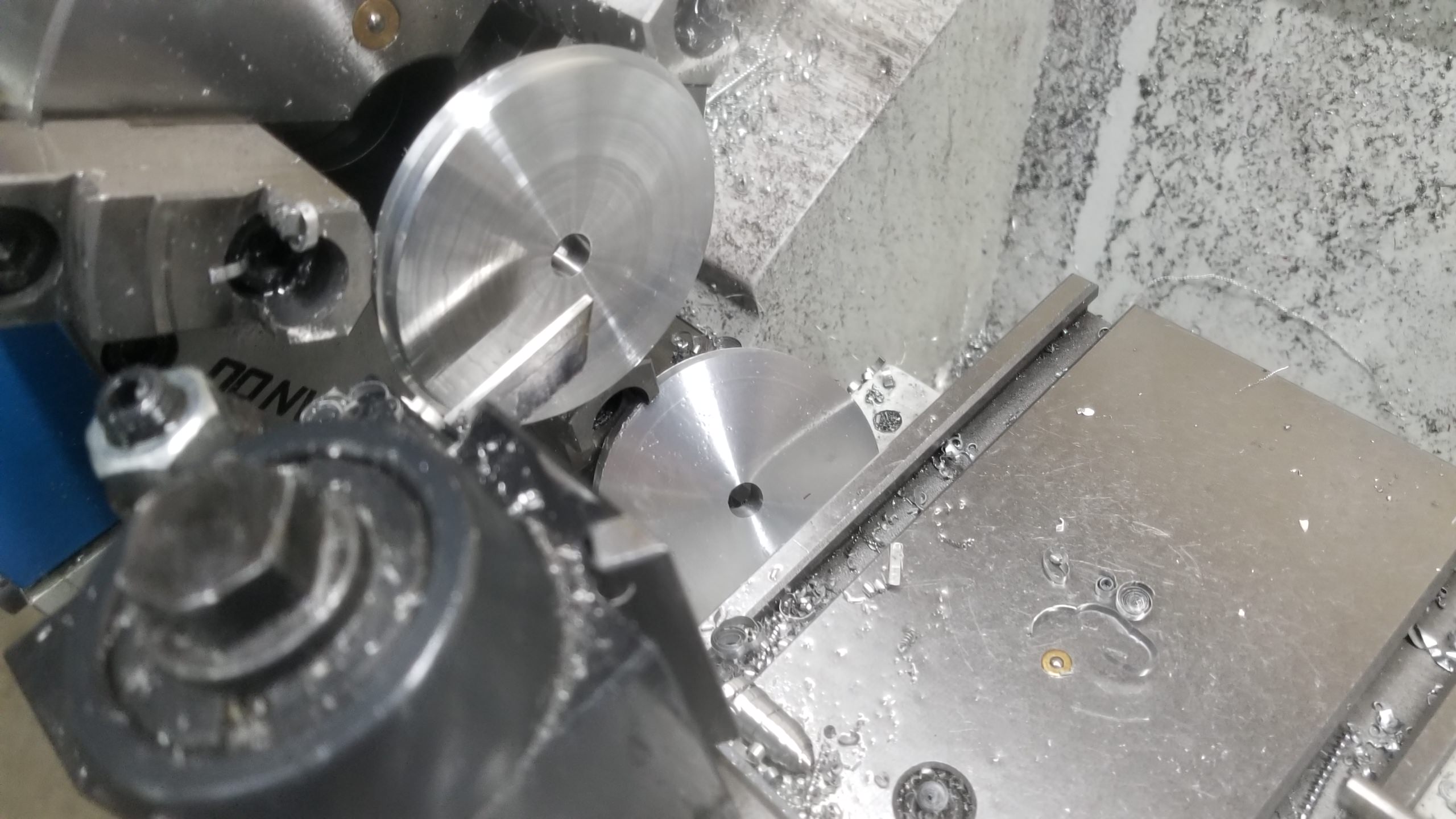

I was parting a piece of 3" aluminum round on the lathe. The chuck was spinning around 150 RPM and I turned the machine off as soon as it finished parting. I just let the part fall, thinking it would plop down like every other thing I have parted on the lathe. Unfortunately, the piece was too wide to fall down through the bed, instead it fell on one of the ways, caught a rotating jaw, and got jammed between the chuck jaw and the carriage. Luckily nothing was damaged but the chuck being forced to stop by the shiny new part you just finished isn't pleasant and could easily have broken something.

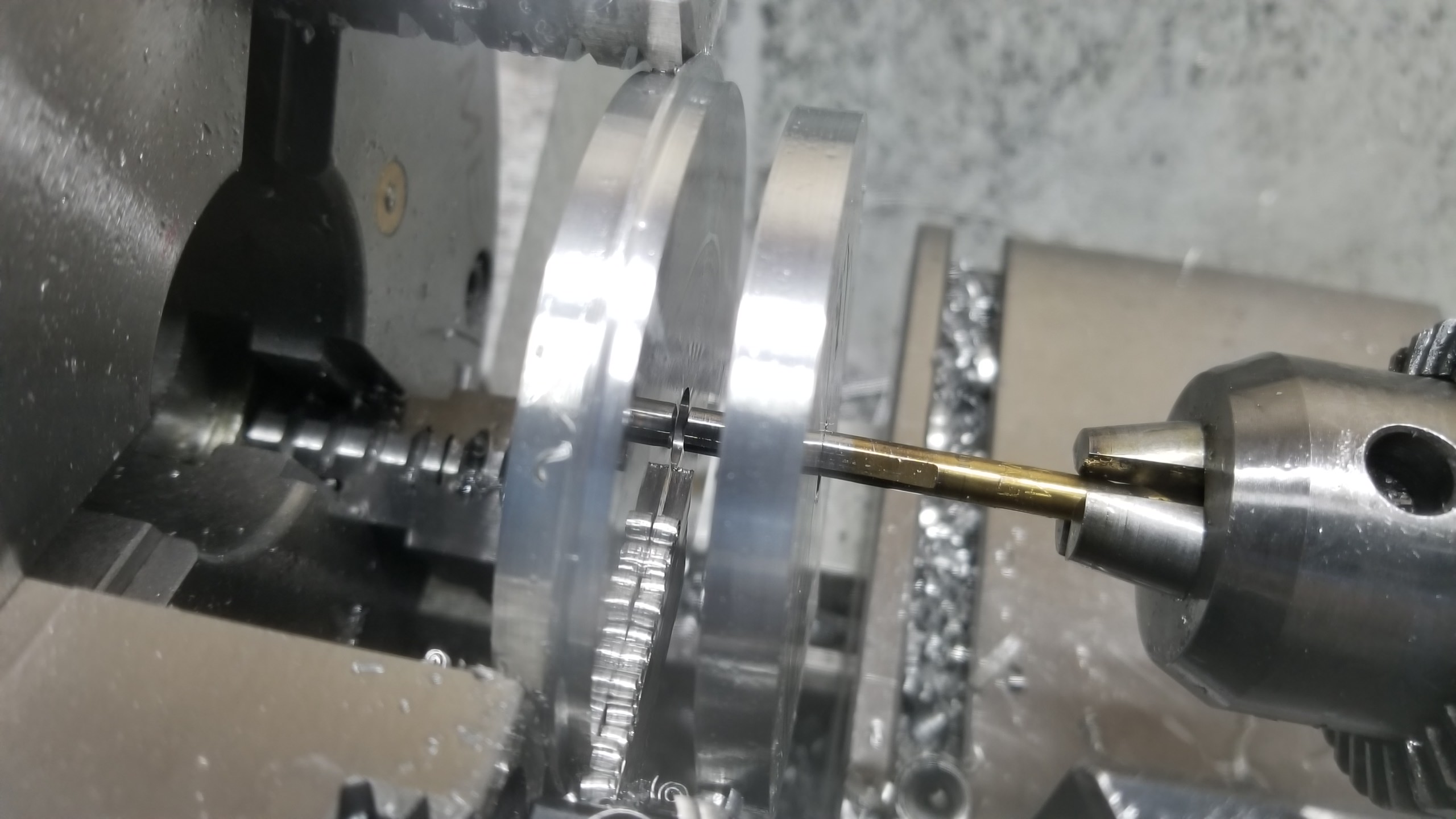

Here are some pictures of roughly what happened. I didn't think to take pictures right after, but this is a dramatic re-enactment hoping it will stop someone from repeating it in the future.

If you stick a drill bit in the chuck backwards and slide it in the hole (if you are parting something with a hole) it can catch it just fine.

Here are some pictures of roughly what happened. I didn't think to take pictures right after, but this is a dramatic re-enactment hoping it will stop someone from repeating it in the future.

If you stick a drill bit in the chuck backwards and slide it in the hole (if you are parting something with a hole) it can catch it just fine.