Novice here. I have read the thread about the Webb/Takisawa TSL-800D with great interest and can see that there are some satisfied owners out there. I am currently looking at a good condition Taiwan unit where the present owner seems not to know much about the machine (I think he is selling from buyer's remorse. He advertised a lovely Clausing 13x40 but when we arrived, began pushing the TSL-800 which he had recently bought and decided he didn't need) The Takisawa is a better size for us, and looks to be in good shape, but has limited tooling (has a 8" 3 jaw Buck chuck, steady rest qctp live and dead centers jacobs chuck, but the 4 jaw chuck he bought he says won't fit) There is no collet closer. It has an A1 spindle mounting system. The motor is a 3-5 hp dual speed 3 phase motor and is a much better size for us than the Clausing. Our intended use is making parts to repair farm machinery and shop projects, one off mostly, no production. The ways are good, head has no vibration or bad sounds and it appears to have little wear.

So here are some questions: is there any availability of used parts for this? I didn't see much on ebay or craigslist. Are there any specialty houses that might carry this sort of thing? I see that Takisawa has a distributor in the US but all the stuff on their site is modern industrial. We would like to get a collet closer (it has none) and if we can't adapt the 4 jaw chuck and faceplate, ones of those (I think this would be possible, even thought the present owner had given up)

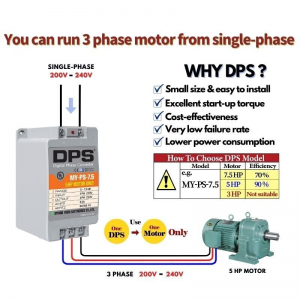

Next, I pretty much know how to set up a variable speed controller to take our shop 220 1 ph to 3 ph, but how do you do it with this dual speed motor? Any special knowledge for that?

Last is price: he says he has "$4000 in it and wants to get his money back" Given the lack of tooling and his obvious desire to get rid of it, I would offer him $3000 and try to get him to throw in something else we can use. He has a nice shop with two Bridgeports, a SB heavy 10, the Clausing and every collet ever made, so I think we could pick up something. Does this price seem reasonable? Any obvious pitfalls I have overlooked?

Any comments are greatly appreciated.