Before you do anything I would test this, Nothing else on your lathe has matched the current diagrams so I would definitely test

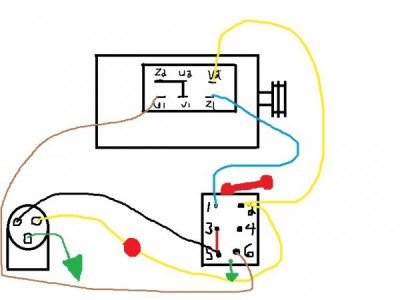

You would have to find the U1, U2, Z1, Z2 wires going to the motor,

You would have to run wires appropriate to the load to your new drum switch

You would have to run power L, N and G to your new drum switch

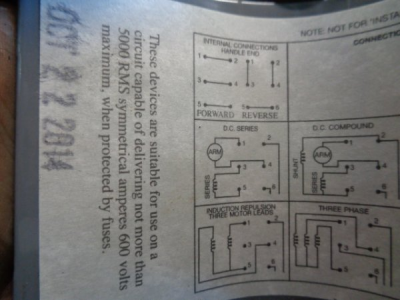

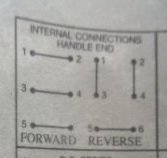

I dont know your new drum switch so you would have to figure out the new switch using an ohm meter to get the appropriate combinations I mentioned above.

The wiring diagram the fella posted earlier has to be for my lathe. No wires have been altered in location. I'm the only one that has ever had access to the lathe.

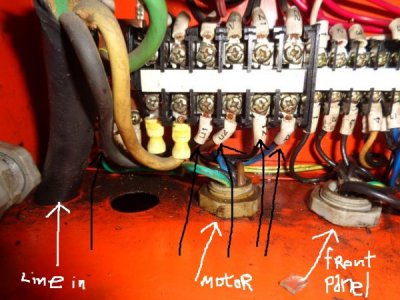

In the picture above, the left gray plastic nut/ferrule with the wires coming thru it and going to the power strip are the only wires leading to the motor.

they are labeled

PE = green/yellow (ground)

U1 = black

U2 = brown

Z1 = black

Z2 = blue

They come from the service access box on the motor, in it's own plastic tube, thru the left gray plastic ferrule and terminate here on this power strip

the 5 wires thru the center gray plastic ferrule is a single harness that goes straight to the estop/powerstart/jog/light user panel on front of lathe

the 5 wires from the right side gray plastic ferrule is the harness straight to the drum switch,

All of these harnesses go straight to their end items, no harnesses split and go off to anything else.

(you can unhook the 5 wires from the drum, then pull the entire harness right out the back of the lathe, same with the other 2 harnesses, just unhook them at one end and pull it thru. So I can "de-wire" all 3 components and have 3 separate 5 wire harnesses laying on the floor in less than 3 minutes.

So knowing that

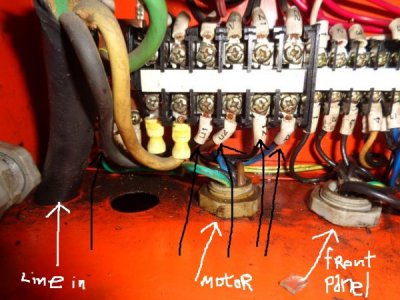

the line in (220v) is the large black lead coming thru the far left bottom of box (large white/black/green wires)

the left gray ferrule are all 5 motor wires,

the center gray ferrule has 5 wires (+ ground) leading to the front user panel,

the right gray ferrule has all 5 wires to the drum switch

how do I proceed to eliminate the user panel and it's harness from the lathe and hook the motor direct to the drum switch?

Thanks,

Mutt