- Joined

- Jun 12, 2014

- Messages

- 4,811

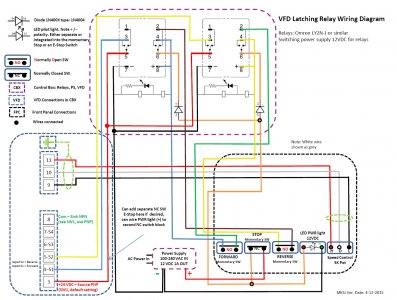

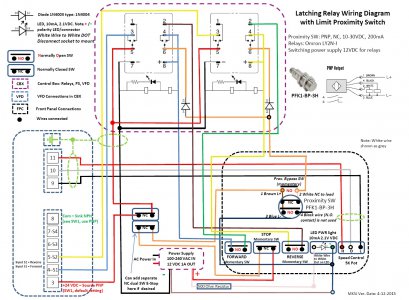

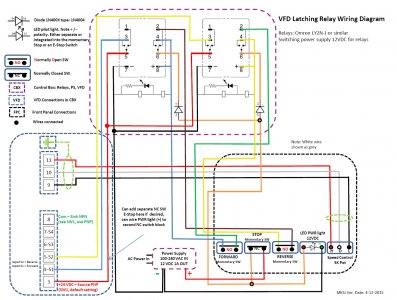

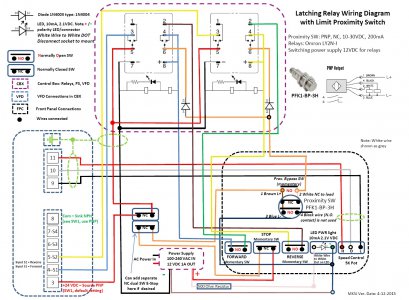

A while back I had a request for a design to use momentary switches on a VFD (TECO JNEV) that did not support 3 wire control. Attached is a schematic using momentary switches and latching relays that could be used on different machines that includes forward/reverse and stop. The left side of the relay is the VFD input controls, the right side of the relay is the latch. They are interlocked so you always need to go through stop to change directions. This was used on a lathe VFD conversion, also very simple and inexpensive. Not sure of the need for a relay coil diode for smaller relays and when using a separate power supply.

Last edited: