-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

X-Y-Z Confusion

- Thread starter Logan Novice

- Start date

- Joined

- Jan 6, 2017

- Messages

- 1,214

So, like this Cadem cnc boring mill, from Cadems website?

A description of the rules, below pic in the link. Cadem is a manufacturer of CNC equipment.

cadem.com

cadem.com

A description of the rules, below pic in the link. Cadem is a manufacturer of CNC equipment.

CNC axes directions on Horizontal Machining centers (HMCs) - Cadem

CNC axes directions always follow a convention, and all CNC machine manufacturers follow this convention. Here's the xplanation for HMCs..

- Joined

- Nov 27, 2012

- Messages

- 7,856

Like when your wife tells you the helicopter light came on in the car. If your a car guy, your first thought Is "huh!?" but there are likely plenty of husband's out there who'd totally understand the reference. And if you both know what she's talking about, does it really matter which word she picks to describe it.

The helicopter light:

Haha, never heard it called the helicopter light before, that's a good one!

Reminds of the guy pooping indicator.

- Joined

- Dec 26, 2015

- Messages

- 2,079

Still ROFLMAO.

- Joined

- Mar 25, 2018

- Messages

- 131

Yeah, Ken, that "helicopter" light is a standard unique to itself. But ... the reset procedures are anything but standard. I guess it's important to have a proprietary helicopter light reset system. Go figure.

As for the X-Y labels. I'll just stick with carriage X and cross feed Y so I don't crash the machine. Now all I have to do is remember the directions for the feed levers.

As for the X-Y labels. I'll just stick with carriage X and cross feed Y so I don't crash the machine. Now all I have to do is remember the directions for the feed levers.

- Joined

- Oct 17, 2018

- Messages

- 922

Here's what I was taught and what I taught my Engineering students:

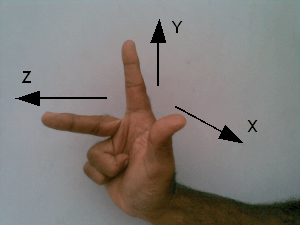

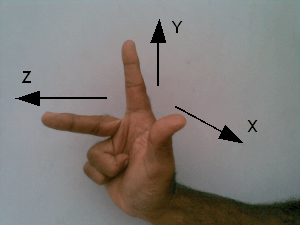

Use the "Right Hand Rule": put your thumb and forefinger on your right hand out like you are making a gun. They will be at right angles to each other in the same plane as your palm. Stick your middle finger out at right angles to your palm ("normal" to your palm, if you prefer that term; it's the same). Your thumb is the X-axis, your pointer finger is the Y-axis and your middle finger is the Z-axis, all pointing in the positive direction. The Z axis is the axis of rotation on any machine.

So a lathe technically doesn't have an X-axis, just Y and Z.

We tend to refer to the left and right direction as the X-axis, and forward and back as the Y and up and down as the Z. Using the RHR gives us a common language and reference for any machine.

Use the "Right Hand Rule": put your thumb and forefinger on your right hand out like you are making a gun. They will be at right angles to each other in the same plane as your palm. Stick your middle finger out at right angles to your palm ("normal" to your palm, if you prefer that term; it's the same). Your thumb is the X-axis, your pointer finger is the Y-axis and your middle finger is the Z-axis, all pointing in the positive direction. The Z axis is the axis of rotation on any machine.

So a lathe technically doesn't have an X-axis, just Y and Z.

We tend to refer to the left and right direction as the X-axis, and forward and back as the Y and up and down as the Z. Using the RHR gives us a common language and reference for any machine.

- Joined

- Jan 6, 2017

- Messages

- 1,214

Here's what I was taught and what I taught my Engineering students:

Use the "Right Hand Rule": put your thumb and forefinger on your right hand out like you are making a gun. They will be at right angles to each other in the same plane as your palm. Stick your middle finger out at right angles to your palm ("normal" to your palm, if you prefer that term; it's the same). Your thumb is the X-axis, your pointer finger is the Y-axis and your middle finger is the Z-axis, all pointing in the positive direction. The Z axis is the axis of rotation on any machine.

So a lathe technically doesn't have an X-axis, just Y and Z.

We tend to refer to the left and right direction as the X-axis, and forward and back as the Y and up and down as the Z. Using the RHR gives us a common language and reference for any machine.

I bet it won't surprise you at all to hear, that's exactly what I was taught. When I was an engineering student.