-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

X1C printer

- Thread starter jarhead

- Start date

Congrats on the new printer. I’ve been making parts on 3d printers for over 10 years. Can’t live without it. I just recently purchased the X1C with AMS to consolidate some of my machines. I gave my Ultimaker 2 and Lulzbot Mini to my son. They are both 3mm filament printers. My Prusa Mk3 is still a workhorse that just works 100% of the time so I am keeping that one for those times I need to work on 2 different parts. The Ultimaker was strictly for PLA, and the Lulzbot was tuned just for PETG, so love that the X1C will print darn near anything on demand. The print quality is just outstanding too.Mine was delivered today and is currently printing a cell phone holder/stand.

Wow these things are cool!

First two prints, phone holder and 427 emblem.

I need to find the thread again where this emblem was generated by another member and thank him.

Need to figure out multiple colors for the emblem.

Could not sleep so I came out to shop at 0500 to build a platform for the printer.

Not fond of the glue stick process

Thanks for looking, and please comment any suggestions or advice of what I may be doing wrong as I start this journey

Joe

I need to find the thread again where this emblem was generated by another member and thank him.

Need to figure out multiple colors for the emblem.

Could not sleep so I came out to shop at 0500 to build a platform for the printer.

Not fond of the glue stick process

Thanks for looking, and please comment any suggestions or advice of what I may be doing wrong as I start this journey

Joe

Last edited:

- Joined

- Mar 23, 2021

- Messages

- 357

I purchased the PEI plate with my X1C and only used the glue stick and included plate once. PEI plate has worked great so far. I just clean it with soap and water and dry with a clean towel after a couple of uses.Not fond of the glue stick process

Thanks for looking, and please comment any suggestions or advice of what I may be doing wrong as I start this journey

Joe

Of course it imprints the plate’s texture, but I like the way it looks.

- Joined

- Jan 6, 2017

- Messages

- 1,214

More work to do on this but it’s coming along. This was my first attempt at multi color

I wonder if your printer would allow the use of a smaller nozzle. A .2mm might produce the detail you need for this part.

I bet if you lower layer size you can get a couple layers on the numbers. It might help clear them up. Another option that I think might work better is to raise them up so that aren't indented, print it face down. Particularly on the textured PEI plate (if you don't have it, get one, seriously nice). Or use the PLA Support with it face down supporting the numbers. Supports that remove without damage takes some getting used to.

A 0.2mm nozzle is available from Bambu for the X1. One downside is that they do require their own accessories for some things. There are third party versions available if you want them. I like the complete hotends for about $35. Quick and easy swaps. I also tried a CHT 0.4mm from Amazon that uses threaded nozzles. It works well, and increases the speed by about 30%. You do need to do a flow test to take advantage of it, so you can configure the slicer properly.

While the speed is awesome, you might gain some quality slowing it down. As nice as the Bambu printers are, the speed can work against you. It might not matter, but do the belt adjustment procedure. It got bounced around etc and it's quick and easy to do, so even if you don't need it, it doesn't take much and might help with fine details a little.

A 0.2mm nozzle is available from Bambu for the X1. One downside is that they do require their own accessories for some things. There are third party versions available if you want them. I like the complete hotends for about $35. Quick and easy swaps. I also tried a CHT 0.4mm from Amazon that uses threaded nozzles. It works well, and increases the speed by about 30%. You do need to do a flow test to take advantage of it, so you can configure the slicer properly.

While the speed is awesome, you might gain some quality slowing it down. As nice as the Bambu printers are, the speed can work against you. It might not matter, but do the belt adjustment procedure. It got bounced around etc and it's quick and easy to do, so even if you don't need it, it doesn't take much and might help with fine details a little.

Havent posted much but have printed allot. Mostly toys for Granddaughter, a few useful things for my wife and daughters.

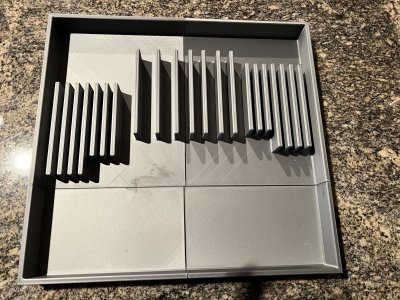

I have printed allot of shop related stuff but this is my first atempt and a part lager than the print bed. I used bambu studio to split it and put in dowels and i must have done something wrong due to the fit. It's PLA and the super glue i had was not good so i ended up filling the voids with JB weld from the bottom after the super glue dried.

The success to me was the amount i learned about Fusion360 with this project.

Thanks for looking, Joe

I have printed allot of shop related stuff but this is my first atempt and a part lager than the print bed. I used bambu studio to split it and put in dowels and i must have done something wrong due to the fit. It's PLA and the super glue i had was not good so i ended up filling the voids with JB weld from the bottom after the super glue dried.

The success to me was the amount i learned about Fusion360 with this project.

Thanks for looking, Joe