-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Y Axis Power-feed For A Benchtop Mill

- Thread starter Dan_S

- Start date

- Joined

- Mar 21, 2013

- Messages

- 4,063

Hey Dan,

Does the Y-axis handwheel and bearing plate extend off the front of your stand? Reason I ask is because when I had the 12z, mine did (not counting the chip tray), and I was seriously considering buying a standard Y-axis PF for a knee mill and making a custom front plate/bearing carrier and shaft extension if needed. But as you know, other events happened that eliminated the need for this project, i.e., bought a new PM935, so I never got past the planning stage.

But I was pretty certain that I could make one work. Now if the Y-axis handwheel doesn't extend beyond the mill's base, then this scenario won't work.

Just a suggestion.

Does the Y-axis handwheel and bearing plate extend off the front of your stand? Reason I ask is because when I had the 12z, mine did (not counting the chip tray), and I was seriously considering buying a standard Y-axis PF for a knee mill and making a custom front plate/bearing carrier and shaft extension if needed. But as you know, other events happened that eliminated the need for this project, i.e., bought a new PM935, so I never got past the planning stage.

But I was pretty certain that I could make one work. Now if the Y-axis handwheel doesn't extend beyond the mill's base, then this scenario won't work.

Just a suggestion.

Last edited:

- Joined

- Aug 26, 2013

- Messages

- 1,061

Gunrunner you need to order a set of these for the Z axis hand crank. Bill did you just spit coffee on your monitor? :rofl:

View attachment 253356

View attachment 253356

- Joined

- Mar 21, 2013

- Messages

- 4,063

Dan, Charles is right in that this would take a bit of thinking/engineering and fab, but I don't think it would be that hard once you get into it. From the pics I would say it's definitely worth looking into.

EDIT: Look at it this way. Once you figure out all the details you could offer your services to others with these machines and maybe get a bit of walking around money for your efforts.

EDIT: Look at it this way. Once you figure out all the details you could offer your services to others with these machines and maybe get a bit of walking around money for your efforts.

I am planning a Y axis power feed for my 932. Searching eBay for "Y axis power feed" will yeild several results of kits that you shouldn't have to modify very much as they come with the Y axis components. They appear to be different than the X axis kits.

Last edited:

Looking at things a little more closley, I'm thinking which ever kit you start with you will need to do some modification....It may be easier to start with the x-axis kit so you get the mounting plate??

I was planning on ordering one of the aSong kits next week and giving this a shot...

I was planning on ordering one of the aSong kits next week and giving this a shot...

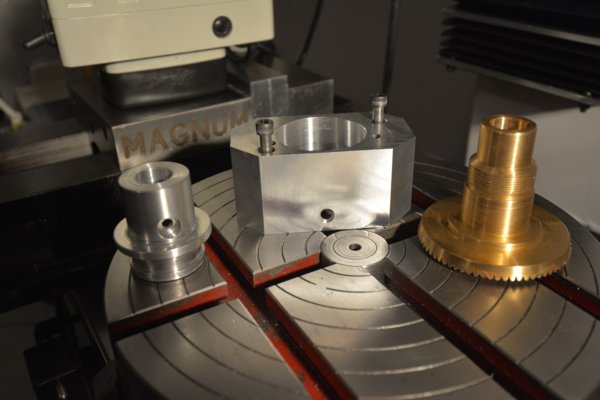

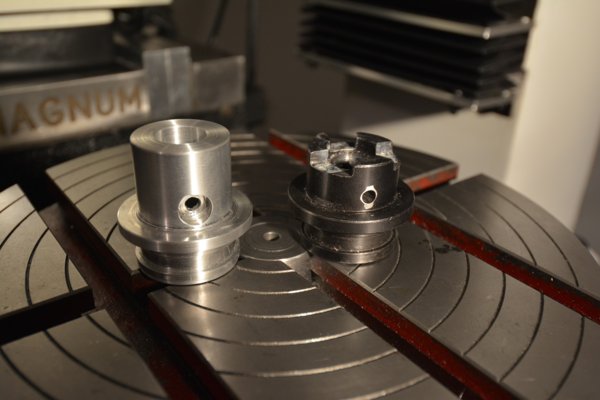

I'm finally getting around to installing my Y axis power feed!! As with any project like this there are several ways to "get there", I thought I'd share what I've come up with, hopefully it will give you some ideas on how to proceed. I don't think there is a true "bolt on" kit available that will fit the benchtop mills, every kit I've seen will need some sort of modification as they are really designed for knee mill instillation. I am not done yet (am waiting on a part) but I will show you what I have thus far:

I made a stand off and a spacer to clear the drip tray on my machine.

The spacer replaces this factory part.

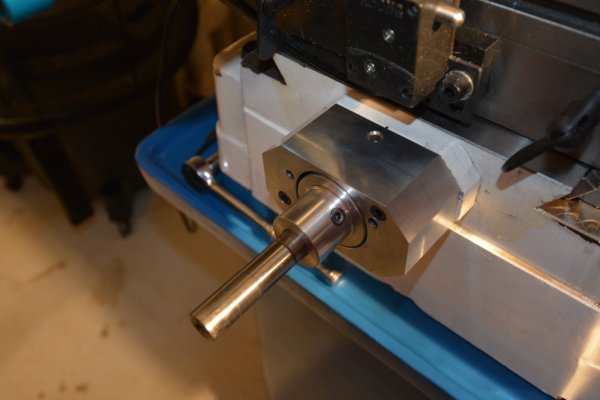

I also extended the shaft.

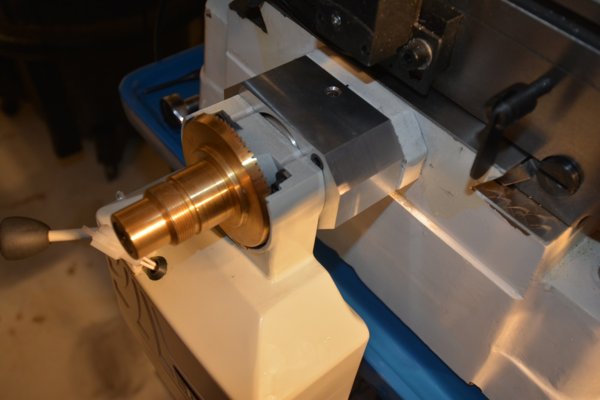

So it looks something like this:

I bought the wrong power feed...This one is designed to be mounted horizontally (that's why the top is chopped off rather than rounded}. Don't get this one, get the one designed to be mounted vertically...

I will post more when I'm finished...

I made a stand off and a spacer to clear the drip tray on my machine.

The spacer replaces this factory part.

I also extended the shaft.

So it looks something like this:

I bought the wrong power feed...This one is designed to be mounted horizontally (that's why the top is chopped off rather than rounded}. Don't get this one, get the one designed to be mounted vertically...

I will post more when I'm finished...

Last edited:

- Joined

- Mar 21, 2013

- Messages

- 4,063

Nice! Yea, when I saw the last picture, I was like 'oh no, that's for the x-axis!' but then realized that you had it figured out already. You could always fab a small cover to protect the gear from chips and whatnot.