- Joined

- Feb 17, 2013

- Messages

- 336

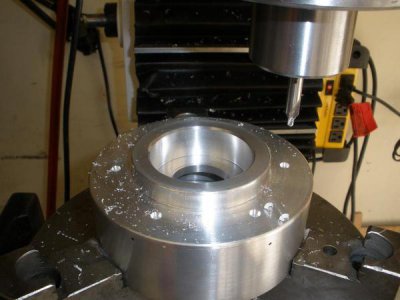

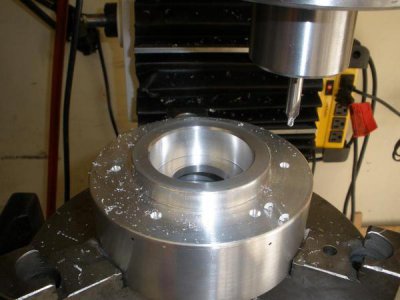

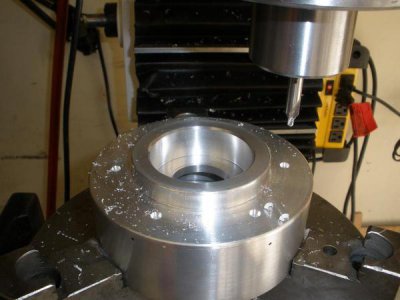

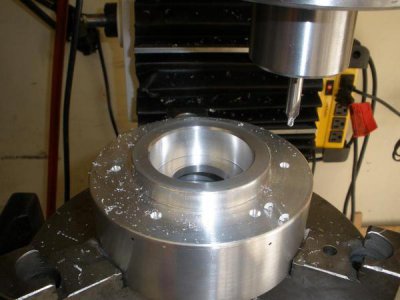

I am starting a new winter project and picked up a very tired 78 XS650 special as the base for it. I'm going the 19" rear wheel route so I bought a 19" front wheel from another Yamaha. I measured the dimensions of the original 16" wheel and used them for dimensions to machine some spacers so the sprocket and brake rotor would be in the stock location in the swingarm when the wheel is centered. I bought a sprocket blank and machined the center hole and bolt hole locations to match the original brake rotor mounting surface on one side of the wheel. I bought a 4.5" chunk of aluminum from the chop bin at the local metal supplier and turned a portion of it to 4.100 which will be the finished OD of the spacers.

Then I cut those slabs off in my band saw and trued them up on the lathe.

This is the brake rotor side.

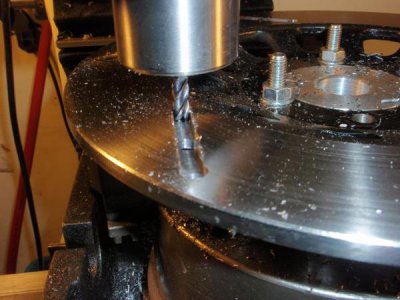

I used 12mm dowel pins inserted in the teeth of the sprocket so I could mount it on center in the lathe and super spacer chucks. That worked very well.

Here's the sprocket I made next to the factory one. I used gunsmith's cold blue to cover the exposed steel area after machining.

Here is the sprockert side spacer. I machined a pocket for an extra wheel bearing in the sprocket holder to help deal with the extra load on that side of the wheel.

I machined a spacer to go between the two wheel bearings and another to go between the sprocket holder bearing and the left wheel bearing. I heated the sprocket holder up to 175 degrees with my heat gun and the bearing dropped right in

Here's the assembled wheel ready to be mocked up in the swing arm.

I clamped a lenght of 1/2" square aluminum shaft to the front sprocket to align the rear sprocket and measured and machined the outer bearing spacers from stainless.

I mounted the front wheel on the forks and shecked the wheel alignment with 2 lengths of straight lumber and it turned out spot on.

Now that this part is done I will strip the entire bike down for re-build.

John

Then I cut those slabs off in my band saw and trued them up on the lathe.

This is the brake rotor side.

I used 12mm dowel pins inserted in the teeth of the sprocket so I could mount it on center in the lathe and super spacer chucks. That worked very well.

Here's the sprocket I made next to the factory one. I used gunsmith's cold blue to cover the exposed steel area after machining.

Here is the sprockert side spacer. I machined a pocket for an extra wheel bearing in the sprocket holder to help deal with the extra load on that side of the wheel.

I machined a spacer to go between the two wheel bearings and another to go between the sprocket holder bearing and the left wheel bearing. I heated the sprocket holder up to 175 degrees with my heat gun and the bearing dropped right in

Here's the assembled wheel ready to be mocked up in the swing arm.

I clamped a lenght of 1/2" square aluminum shaft to the front sprocket to align the rear sprocket and measured and machined the outer bearing spacers from stainless.

I mounted the front wheel on the forks and shecked the wheel alignment with 2 lengths of straight lumber and it turned out spot on.

Now that this part is done I will strip the entire bike down for re-build.

John