- Joined

- Dec 22, 2015

- Messages

- 561

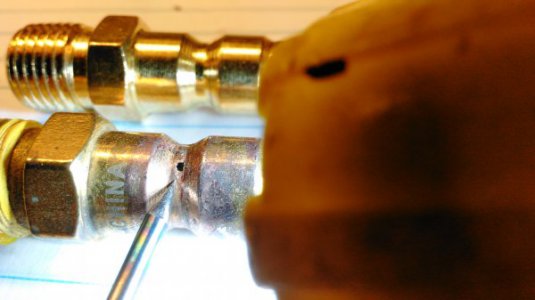

This is a square broach I made just to see if it would work. I don't have any current need for a square hole but who knows I might someday.

I started with a 1/2" square rod 8" long and cut 12 grooves about 0.300 apart , 0.100 wide, and a little under 1/2" diameter. Turned the starting end to just under 1/2" and about 5/8" long. Then using the compound set at 3 degrees proceeded to cut each land about 0.013 smaller than the one before it and ended up with 13 cutting spaces.

Drilled a 1/2" hole in some 1/4" aluminum scrap and pushed the tool through with the press. It worked quite well without much force but when the last land broke through the bottom it left a jagged square hole. I tried a couple more but this time I stopped two lands before breaking through the bottom. I then turned the plate over and finished the broach coming in from the other side. Much better finish and even in 1/2" material the press wasn't straining.

This is just mild steel from the box store and not hardened.

View attachment 137844

Thanks for looking

Ray

Great idea!! I wonder if the same approach could be used to make a broach for mild steel, maybe using hardenable steel.