Episode 4 || (Mis-) Adventures in Dissolving a Broken Tap

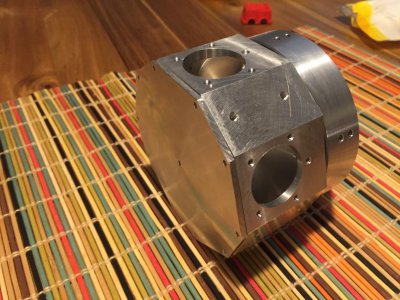

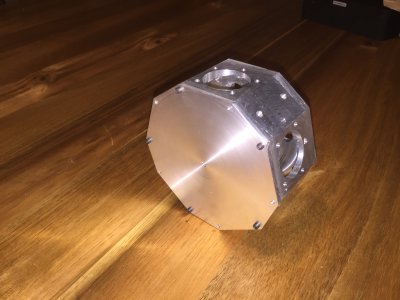

As I stated in a prior post, I broke off a #4-40 tap in the (beautiful) crankcase I had just completed. I tried the usual 'grab it with a vise grip and twist' technique with no luck. And a #4-40 is so small, there's no real way to get a traditional tap extractor on it (and would almost certainly not of worked anyway, because they never work). I don't have a welder, so no ability to weld a nut to it. I have a few carbide drill bits and end mills on hand, but none small enough to drill out such a small tap.

As was suggested by

@Lo-Fi a few posts back, I had recently come across a video or two on YouTube showing how one could dissolve a broken HSS tap out of a chunk of aluminum using the proper mixture of chemistry and witchcraft. I thought to myself, this would be a perfect opportunity to try it out for myself. After all, a #4-40 tap is small so it shouldn’t take all that long to dissolve.

So I got to re-watching those YouTube videos. They all make it look incredibly easy. The sorcery basically goes like this: let the broken tap in your part sit submerged in a saturated, near-boiling solution of alum and water. After a few hours, the tap will be completely dissolved, and the part will be completely spared, save for maybe a little bit of cleanup. Sounded good to me!

So I got started.

Step 1.

I had never even heard of alum before watching those videos. So I was surprised that you can find it in a regular spice container at any grocery store. I guess it's used for canning or pickling or something. My local grocer only had 4 little containers of it, so I bought it all. Didn’t know if that was too much or too little, but it was pretty cheap. Maybe $4 per canister or something.

Step 2a.

Step 2a.

This was an embarrassing failure on my part. And I originally took a couple photos, but deleted them because it was so dumb. I’m going to share anyway. Oh well.

I grabbed one of my wife’s small Pyrex food storage containers and filled it about 2 fingers full with water, just deep enough so I could put my part in and submerge the tap. I then dumped one of the containers of alum in and stirred it around a bit. I then put it on the gas stove directly over the open flame. Well, that was stupid. The Pyrex neatly broke into a few pieces after a couple minutes, dumping hot alum-water all over the stove. See, I had always thought Pyrex was made from borosilicate glass, which is what is used in chemistry labs world-over and exposed directly to Bunsen burners and the like. I was wrong, it’s not. (To be fair to me, Pyrex

used to be made from borosilicate glass until something like the mid-90s, and

still is made from borosilicate glass across the pond. So our Euro brethren shouldn’t have much the same experience.)

Step 2b.

I wised up right-quick and switched over to a crockpot. I similarly put in just enough water, and dumped in an alum canister. All that dissolved at room temperature, so I dumped in another. I dropped in the part and cranked up the crock. About halfway through, I dumped in my final alum canister. While I’m not sure I ended up with a completely saturated solution, it seemed pretty darn concentrated to me.

Step 3.

Step 3.

I waited. And waited.

~75F: nothing.

~100F: nothing.

~125F: nothing.

~150F: nothing.

~175F: nothing.

Finally, at somewhere around 200F (not exactly sure, but it was hot), a steady stream of bubbles started coming off the tap. WAHOO! It was working!

So then I waited some more, the plan was to wait until all the bubbles were gone, which would obviously signify that the tap was gone.

After something like 5 hours, the bubbles coming from the tap had largely abated. There were still some bubbles forming, but they were coming from other parts of the crankcase and didn’t have the same vigor as before.

Step 4.

Having waited long enough, or as long as I was willing to wait anyway, I pulled the part out and rinsed it off. As I had been checking things the whole way along, I was both dismayed and unsurprising to find (1) the tap was completely intact, and (2) my part was a now a complete mess, not only below the waterline, but everywhere.

It was a little bit hard to tell whether the grossness on the surface of my crankcase was due to pitting or buildup. Buildup is in theory clean-able; pitting, not so much. I suspect it was a buildup of alum, but couldn’t be sure. Seemed to be some pitting as well, though I'm not sure the chemistry going on supports that hypothesis.

I briefly tried cleaning up the surfaces, but geez, it was a huge pain in the ass. And because of the weird geometry, I’m sure there would have been large areas that never got cleaned up, and big scratches and gouges in other parts of it.

It was ugly now and would always be ugly.

So I decided to scrap the part and start again.

This would afford me the opportunity to fix some of my prior mistakes, so I wasn’t all that bummed. In fact, it was a pretty fun part to make, so spirits are still high.

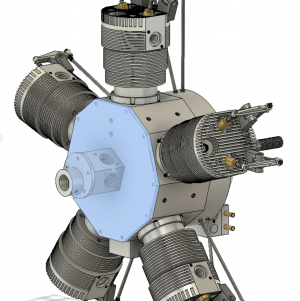

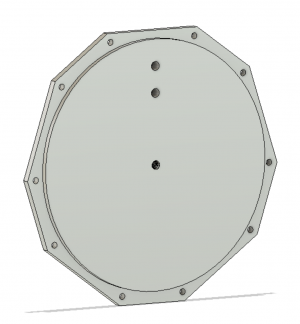

My next post will be a relatively short one about re-making the crankcase.

TIME ON TAP REMOVAL: 2 hours

CUMULATIVE TIME: 50 hours