-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

- Forums

- THE PROJECTS AREA

- PROJECT OF THE DAY --- WHAT DID YOU DO IN YOUR SHOP TODAY?

- Project of the Day Mega-Thread Archives

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2015 POTD Thread Archive

- Thread starter jumps4

- Start date

Cool, looks like some of the jobs I do at work. You must work in basically a repair shop like I do. One off repairs and basically a lot of different jobs. I will have to take a pic of all these sprockets I have had to modify over the last week or so. Enjoyed the pics, really hit home for me.

- Joined

- Jan 10, 2013

- Messages

- 176

Not really machinery related, but I did successfully replace the broken screen in my Kindle book reader. Not that difficult, but fussy. An instructable helped a lot:

http://www.instructables.com/id/Fix-your-broken-Kindle-Keyboard-Screen/

A new one is only 3 times the cost of the screen, but mine has 3G wireless and a bunch of arcane .pdf documents loaded on it. I'm happy to have it back!

http://www.instructables.com/id/Fix-your-broken-Kindle-Keyboard-Screen/

A new one is only 3 times the cost of the screen, but mine has 3G wireless and a bunch of arcane .pdf documents loaded on it. I'm happy to have it back!

- Joined

- Aug 22, 2012

- Messages

- 4,121

I haven't been getting as much time in the shop as I would like lately.

It seems things keep conspiring against me to prevent me from working, such as these little fellows who keep entering my shop and begging me for food.

Still, who could resist them. Eventually I managed to use my new 4 jaw chuck for the first time since I finished the back plate.

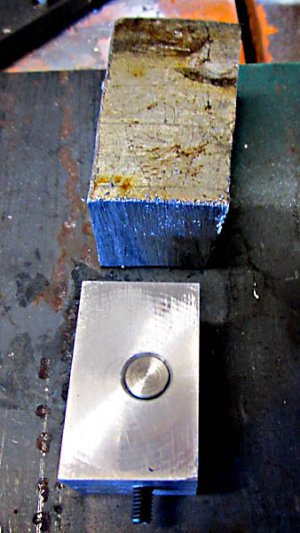

I cut a chunk off this lump of gnarled aluminium and squared it up.

Not gauge block standard but pretty good for all that.

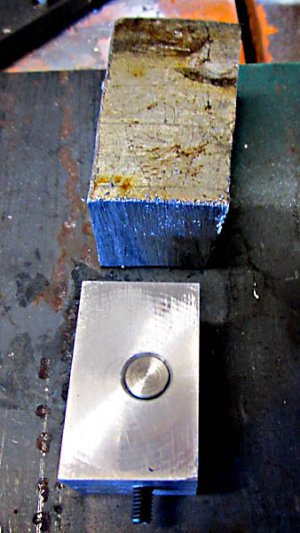

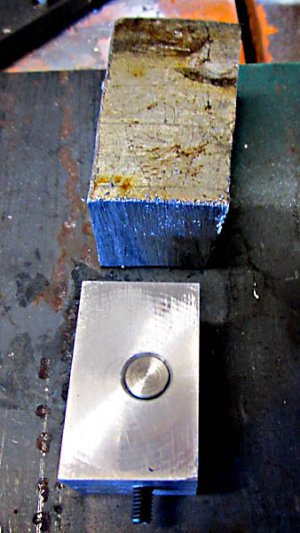

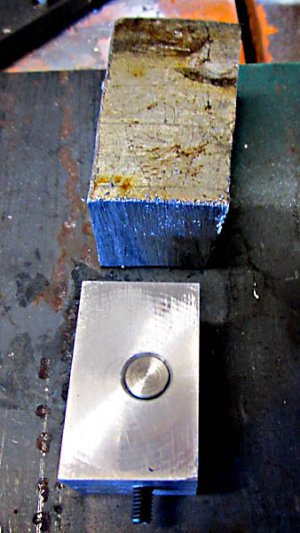

I need 8 x8mm cylinders with a 5mm dia hole through 4 of them and a 4mm tapped hole in the other four so decided to make this block into a jig so I could drill them all the same and also use the block as a tapping guide.

The grub screw holds the stainless cylinders in the jig.

The idea is to use them as clamp bolts for the bearings on my refractor.

Hopefully they will be inset inside the bearing blocks (still to be bored to size and split) in this position.

Only the ends of the cylinders will show with larger knurled nuts on their ends.

It seems things keep conspiring against me to prevent me from working, such as these little fellows who keep entering my shop and begging me for food.

Still, who could resist them. Eventually I managed to use my new 4 jaw chuck for the first time since I finished the back plate.

I cut a chunk off this lump of gnarled aluminium and squared it up.

Not gauge block standard but pretty good for all that.

I need 8 x8mm cylinders with a 5mm dia hole through 4 of them and a 4mm tapped hole in the other four so decided to make this block into a jig so I could drill them all the same and also use the block as a tapping guide.

The grub screw holds the stainless cylinders in the jig.

The idea is to use them as clamp bolts for the bearings on my refractor.

Hopefully they will be inset inside the bearing blocks (still to be bored to size and split) in this position.

Only the ends of the cylinders will show with larger knurled nuts on their ends.

- Joined

- Feb 7, 2013

- Messages

- 2,487

Nice post! I especially like the photo of you with the birds!

I have several pigeons so enjoy birds and machining as well.

Last winter I kept one in the shop and he perched over the

lathe and kept me company. This year they have an outside

cage and building. What kind of birds are those?

I have several pigeons so enjoy birds and machining as well.

Last winter I kept one in the shop and he perched over the

lathe and kept me company. This year they have an outside

cage and building. What kind of birds are those?

I haven't been getting as much time in the shop as I would like lately.

It seems things keep conspiring against me to prevent me from working, such as these little fellows who keep entering my shop and begging me for food.

View attachment 94871

Still, who could resist them. Eventually I managed to use my new 4 jaw chuck for the first time since I finished the back plate.

I cut a chunk off this lump of gnarled aluminium and squared it up.

View attachment 94874

Not gauge block standard but pretty good for all that.

I need 8 x8mm cylinders with a 5mm dia hole through 4 of them and a 4mm tapped hole in the other four so decided to make this block into a jig so I could drill them all the same and also use the block as a tapping guide.

View attachment 94875

The grub screw holds the stainless cylinders in the jig.

View attachment 94876

The idea is to use them as clamp bolts for the bearings on my refractor.

View attachment 94873

Hopefully they will be inset inside the bearing blocks (still to be bored to size and split) in this position.

View attachment 94872

Only the ends of the cylinders will show with larger knurled nuts on their ends.

- Joined

- Oct 4, 2011

- Messages

- 727

Are those magpies? I love those, we don't have them here in the states but they are very cool. Also nice use of the 4 jaw. I love how machining can take such a gnarly piece of metal and make into something useful and cool looking.

Jeff

Jeff

I haven't been getting as much time in the shop as I would like lately.

It seems things keep conspiring against me to prevent me from working, such as these little fellows who keep entering my shop and begging me for food.

View attachment 94871

Still, who could resist them.

- Joined

- Jan 27, 2015

- Messages

- 7

I've not managed to get into the shop for the last few days, and I don't suspect I'll get away with spending much time in there tomorrow. But I did manage to work a little bit on the ever ongoing "tidy up".

I have quite a bit of 25mm thick polyethylene foam, and the plastic cases are available locally for next to nothing. I think this might be a decent way of keeping the tools sorted

I have quite a bit of 25mm thick polyethylene foam, and the plastic cases are available locally for next to nothing. I think this might be a decent way of keeping the tools sorted

- Joined

- Dec 22, 2012

- Messages

- 328

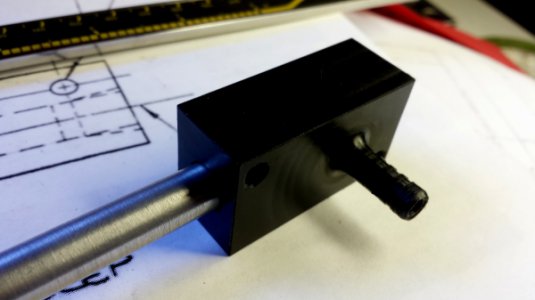

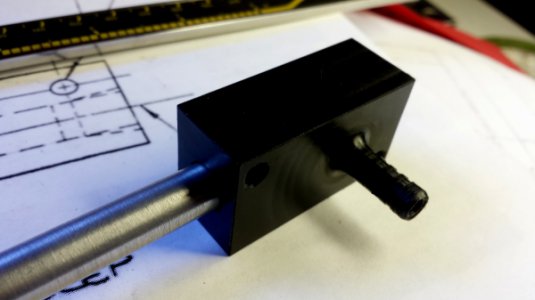

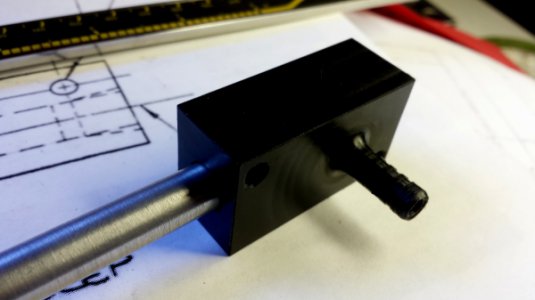

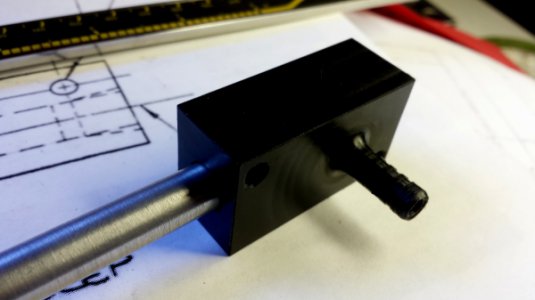

Pitot tube fabrication

Well, I guess you won't see this every day: I used the mill, the lathe, and a small metal brake to fabricate a new pitot tube and mount for the plane I'm building. The pitot tube supplies ram air pressure to the airspeed indicator, through a long vinyl hose threaded through the wing. I chose Delrin for the block because it's lighter, and I machined the hose fitting as an integrated feature. All this saves 3-4 ounces off the weight when compared to the "usual" materials. Lower weight = better aircraft performance. A few ounces here and there adds up to a significantly lighter aircraft in the end.

Tom

Well, I guess you won't see this every day: I used the mill, the lathe, and a small metal brake to fabricate a new pitot tube and mount for the plane I'm building. The pitot tube supplies ram air pressure to the airspeed indicator, through a long vinyl hose threaded through the wing. I chose Delrin for the block because it's lighter, and I machined the hose fitting as an integrated feature. All this saves 3-4 ounces off the weight when compared to the "usual" materials. Lower weight = better aircraft performance. A few ounces here and there adds up to a significantly lighter aircraft in the end.

Tom

![0211151507a[1].jpg 0211151507a[1].jpg](https://www.hobby-machinist.com/data/attachments/52/52208-fcd78fa1c6a8c92ed38684831cd9a79d.jpg)

![0213150841[1].jpg 0213150841[1].jpg](https://www.hobby-machinist.com/data/attachments/52/52209-ed65737c2618a55e47be62b603f957e3.jpg)