-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

- Forums

- THE PROJECTS AREA

- PROJECT OF THE DAY --- WHAT DID YOU DO IN YOUR SHOP TODAY?

- Project of the Day Mega-Thread Archives

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2013 POTD Thread Archive

- Thread starter HMF

- Start date

Looks great, and is functional, wonderful having things where you can get to them when you need them.I finally did something for just me. the neighbor had a bunch of walnut that he sawed up into planks and boards, and I just shamelessly needed to have one for something or other. well, this is the "other" for me. sawed to length, ran it thru the planer and drilled a few holes in it, made some brackets that slip between the mill and the stand and installed it. the poly varnish finished it off quite nicely. not fancy just function.

View attachment 55083View attachment 55084

M.L.

T

TOOLMASTER

Forum Guest

Register Today

In my opinion, Davidh, that's a damned pretty job! And functional, too!

- - - Updated - - -

Well, today I decided to try to cut a large 1" steel plate so I can strengthen my milling machine back and table (trying to reduce vibration to as close to 0 as I can). Decided to prop the plate up on buckets and use a grinder to cut it (ran out of o2 for the torch and its too think for the plasma cutter). Got one end on a bucket and as I lifted the other end it dropped and smashed the two middle fingers on my left hand (really something I dont ever want to repeat). Normally this sort of thing only hurts for a while, but I guess the fact the plate is 160 lbs its going to hurt for a long timeDid manage to grind about 1/2 way through before giving up for the day and soaking my fingers in cold water. With any luck I didnt smash the bones, but so far I can still move them pretty well. Willl see what they are like tomorrow.

OUCH!

- Joined

- Mar 14, 2013

- Messages

- 443

Today I finished mounting a Z-axis DRO (a used Mitutoyo, sorry no pics) on my Jet 15 mill. Yesterday I finished making a froe for splitting wood. Most froes are larger... large ones were used in the old days for making wood shingles, smaller "cooper's froes" were used for making barrel staves; I needed one smaller than I've ever heard of for some projects I'm working on.

The blade is A2... I had to first make a fixture to hold it at the right angle while I milled the bevels, torch hardened it along the cutting edge, drew it down in a toaster oven, and touched up the edge with a stone. The handle is A2 as well, not because it needed to be but because it was the only piece of round stock the right size I had on hand.

Tried it out, and it sure is easier than using a chisel, knife, and wooden wedges!

The blade is A2... I had to first make a fixture to hold it at the right angle while I milled the bevels, torch hardened it along the cutting edge, drew it down in a toaster oven, and touched up the edge with a stone. The handle is A2 as well, not because it needed to be but because it was the only piece of round stock the right size I had on hand.

Tried it out, and it sure is easier than using a chisel, knife, and wooden wedges!

- Joined

- Nov 21, 2010

- Messages

- 1,602

What Did You Do in Your Shop Today? One dirty job

One hated dreaded dirty job. Friday customer with two front truck rotors. Im tackin another $10 for aggrevation. Have to use the ole GK1918

cause its got the capacity. Just a word, no amount of newspapers rags, anything, just terrifire,ing. I probably took .010 of each (4 sides) that

caused the rest of the day to clean up. Cast dust fillings mixed with rust all over me, walls, floor, lathe was green^%^&@ Im thinking this

maybe the last drum, rotor job-dont need it. For the new people thats the GK in my user box that was green!!

One hated dreaded dirty job. Friday customer with two front truck rotors. Im tackin another $10 for aggrevation. Have to use the ole GK1918

cause its got the capacity. Just a word, no amount of newspapers rags, anything, just terrifire,ing. I probably took .010 of each (4 sides) that

caused the rest of the day to clean up. Cast dust fillings mixed with rust all over me, walls, floor, lathe was green^%^&@ Im thinking this

maybe the last drum, rotor job-dont need it. For the new people thats the GK in my user box that was green!!

- Joined

- Jan 22, 2011

- Messages

- 8,031

Back when I bothered with drums and rotors, i got so aggravated that I bought a brake lathe. They're built for it and make the job simple. Not pleasant, but made for the job, so no real bother. And around here, it seems everyone it quitting the brake turning business anyway, so there are several lathes for sale. I won't even do my own on my machines.

- Joined

- Mar 10, 2013

- Messages

- 324

As some may know I build large scale gasoline rc boats. Recently while working on the fuel system I spilled some fuel from my fuel lines in the hull .

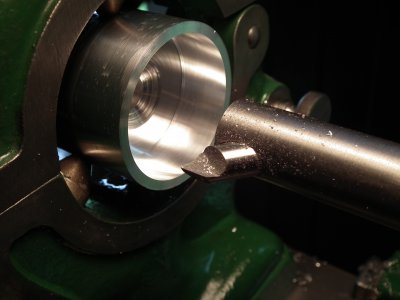

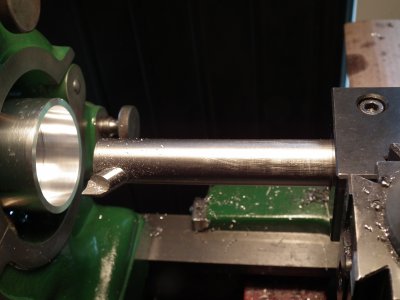

I got bored today and made these from the stainless shaft from an old printer I stripped down.

A simple project but satisfying

They are fuel line plugs 3 different sizes 5mm , 4.5mm and a 4mm

I got bored today and made these from the stainless shaft from an old printer I stripped down.

A simple project but satisfying

They are fuel line plugs 3 different sizes 5mm , 4.5mm and a 4mm

- Joined

- Jun 22, 2012

- Messages

- 1,552

I know what you mean, you can buy a new rotor for just a bit more than turning one, of course it's chinese, but that's the way things are now. I see brake lathes on craigslist all the time in the Detroit area. It will be a lost art too.Back when I bothered with drums and rotors, i got so aggravated that I bought a brake lathe. They're built for it and make the job simple. Not pleasant, but made for the job, so no real bother. And around here, it seems everyone it quitting the brake turning business anyway, so there are several lathes for sale. I won't even do my own on my machines.