T

TOOLMASTER

Forum Guest

Register Today

LOL:roflmao:

Today i ran 1/2 PVC pipe along the perimeter of my barn "Teeing" off every 8 feet so I could have ready available air at my machinery and not taking the risk of tripping over the hose running on the floor. It worked well, put 2 regulators, one on hose reel for auto and another for machine air for tools.

Pmedic828,

pvc is not a good idea for air. pvc can shatter and throw shrapnel . I worked with a guy that ended up losing eyesight in both eyes while wearing safety glasses .

Mike

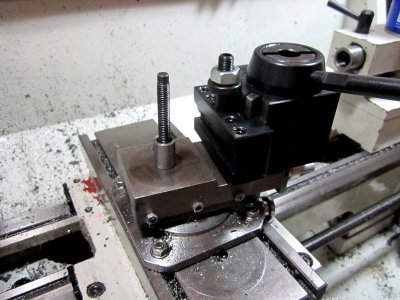

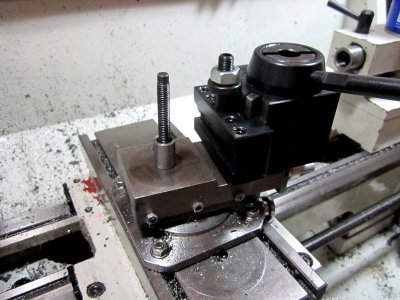

Im only a couple months into this whole hobby machinist thing and am pretty much self teaching. I had a chunk of aluminum laying around so I made up this little pulley. It wasn't made for anything I just wanted to try and make one. I am having a blast making useless items just to get familiar with the lathe and such.

View attachment 57962

Yes, like the rest of us you will find great satisfaction in spending thousands of dollars to make $10.00 items you can purchase at Lowes. BUT WHAT A SATISFACTION OF SAYING "I BUILT IT!" and having your friends say, every time they great you, "AND WHAT HAVE YOU MADE LATELY?"

M.L.Woy

Hee hee - My wife told me there are things I shouldn't quote to her. This message being one of those. :-D

Sent from my Xoom using Tapatalk 4 Beta

My wife started-in on this one time and I came back with "Well maybe you don't need to spend 40 bucks on a tube of lipstick -which has no return on investment at all". Things got real quite after that -and still are a couple years later. -Guess I told her :LOL:...

Ray