-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

- Forums

- THE PROJECTS AREA

- PROJECT OF THE DAY --- WHAT DID YOU DO IN YOUR SHOP TODAY?

- Project of the Day Mega-Thread Archives

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2013 POTD Thread Archive

- Thread starter HMF

- Start date

- Joined

- Jul 14, 2013

- Messages

- 198

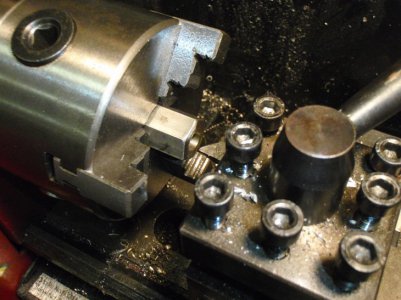

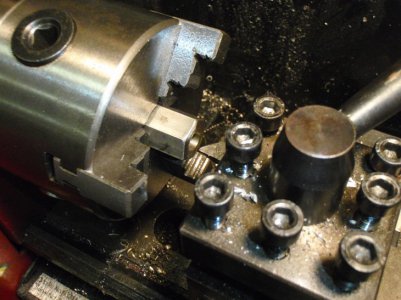

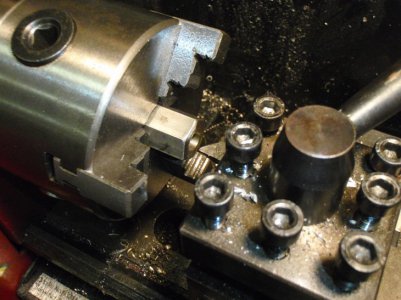

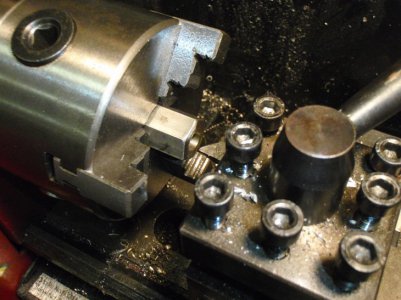

After putting it off, I finally bored out my 7x10 3 jaw chuck to full 3/4"

Now I can put 3/4" stock throught the chuck.

Many have ground the back cover screws to clear, but I used sockethead caps screws cut to a head diameter of .070

that means I don't have to index the screws in the same holes next time I disassemble the chuck.

Now I can put 3/4" stock throught the chuck.

Many have ground the back cover screws to clear, but I used sockethead caps screws cut to a head diameter of .070

that means I don't have to index the screws in the same holes next time I disassemble the chuck.

- Joined

- Jul 14, 2013

- Messages

- 198

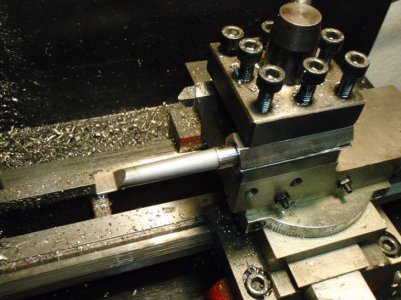

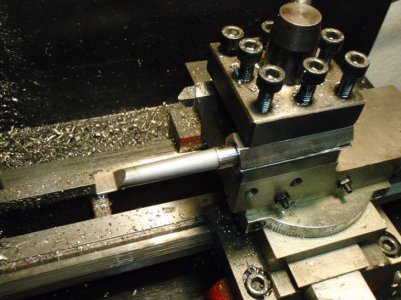

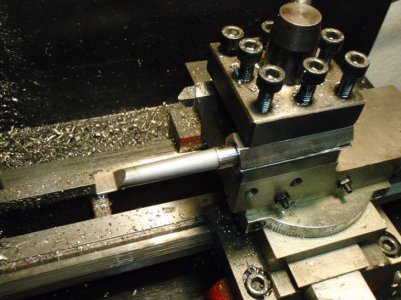

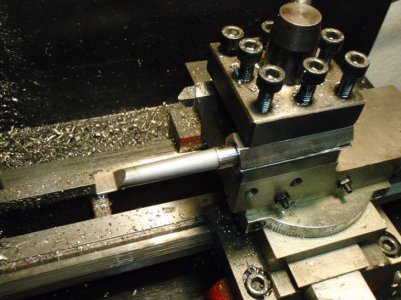

Now that I bored out my chuck to 3/4" I can fit 5/8" hex bar too, so I made the boring bar holder I've been planning:

Face and center drill the 5/8" steel hex bar,

Drill out (5/32, then 5/16)

(the 5/16 drill ended up almost 11/32 with a new Chicago Latrobe bit!)

Ream to 3/8",

A little counter-sink,

Cut to about 2", face and countersink the other side,

Getting there,

Cut a slit to allow clamping screws on tool post to tighten the block,

A quick hit on the buffing wheel to make it shine,

Ready for my next adventure in boring

(Now I need to start a new project to try it out!)

Face and center drill the 5/8" steel hex bar,

Drill out (5/32, then 5/16)

(the 5/16 drill ended up almost 11/32 with a new Chicago Latrobe bit!)

Ream to 3/8",

A little counter-sink,

Cut to about 2", face and countersink the other side,

Getting there,

Cut a slit to allow clamping screws on tool post to tighten the block,

A quick hit on the buffing wheel to make it shine,

Ready for my next adventure in boring

(Now I need to start a new project to try it out!)

- Joined

- Feb 26, 2013

- Messages

- 59

It's been a lot longer than a day in the shop but I finished a DIY cnc router. My own design. Got my key for mach3 yesterday, went out to the shed and the hard drive failed. Now to get another PC.

And yes I know I should clean the shop and finish the wall. Blah blah.

Sent from my iPhone using Tapatalk 2

And yes I know I should clean the shop and finish the wall. Blah blah.

Sent from my iPhone using Tapatalk 2

- Joined

- Feb 19, 2013

- Messages

- 220

Today i ran 1/2 PVC pipe along the perimeter of my barn "Teeing" off every 8 feet so I could have ready available air at my machinery and not taking the risk of tripping over the hose running on the floor. It worked well, put 2 regulators, one on hose reel for auto and another for machine air for tools.

- Joined

- Jun 11, 2013

- Messages

- 731

I did some things with the kids. Post in this thread. http://www.hobby-machinist.com/showthread.php/16789-kids-when-will-they-ever-learn

Steve

Steve

Today i ran 1/2 PVC pipe along the perimeter of my barn "Teeing" off every 8 feet so I could have ready available air at my machinery and not taking the risk of tripping over the hose running on the floor. It worked well, put 2 regulators, one on hose reel for auto and another for machine air for tools.

Pmedic828,

pvc is not a good idea for air. pvc can shatter and throw shrapnel . I worked with a guy that ended up losing eyesight in both eyes while wearing safety glasses .

Mike

- Joined

- Nov 16, 2012

- Messages

- 5,596

Started to make a pair of 45[SUP]o[/SUP] vise jaws for a quick way of holding something in the mill. I really hate swinging the mill head and losing tram. While I'm at it, I'll probably make a 60[SUP]o[/SUP] set too. These will be reversible and can be flipped around. Anyhow, these are rough cut and the metal is 4150. It's HR now so I'll make the basic forms heat treat them to 55 RC grind them precisely and hopefully use them for the rest of my life.

Any ideas for other common angles?

Ray

Any ideas for other common angles?

Ray

- Joined

- Nov 8, 2011

- Messages

- 1,678

Super cool!!!!! :man::man:I may have to steal the idea, just the concept not make one like yours.