- Joined

- Mar 14, 2013

- Messages

- 443

Freehand machining

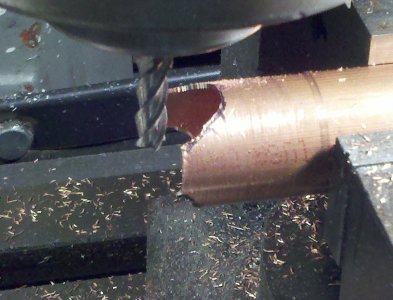

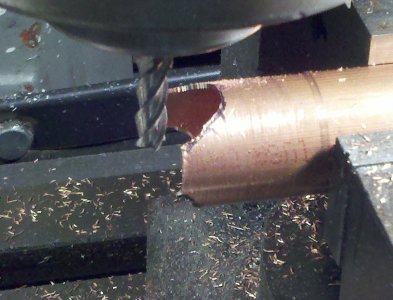

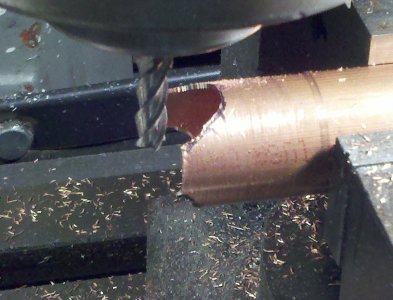

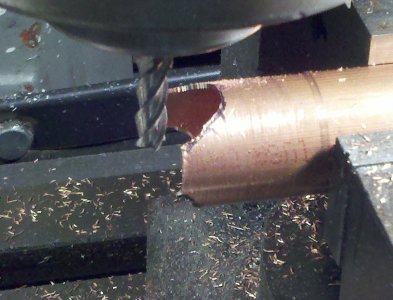

I probably do more wood than metalworking, but sometimes I can combine the two. This time it was a decorative copper cover for some lamps I was making. One had a straight end and was no problem, but the other had to be cut to match the wood of the lamp. First I traced the shape onto a short piece of 1" copper pipe using a caliper and a sharpie pen. I could have done the whole job, slowly, with a hand grinder or (even slower) a file, but with a new (to me) mill, that just seemed silly. I figured I could get close spinning the cranks freehand, so I clamped the pipe in a v-block and started in on it:

Remember Etch-A-Sketch, and how hard is to do angles and curves with it? Same here. Of course, I had to rotate the tube a few times but I got it close, then finished the job with few trial fittings and a Dremel flex shaft with HSS cutter.

Without the copper pipe it looks like this:

And the final result (two of a matched set of four for my cabin, the other two still in progress:

I would like to find a way to keep the copper shiny and bright. I'm told laquer, but I don't know what kind. Alcohol solvents (like in the shellac I use on the wood) are said to darken copper, but it hasn't (yet) on a test piece I shellacked.

I probably do more wood than metalworking, but sometimes I can combine the two. This time it was a decorative copper cover for some lamps I was making. One had a straight end and was no problem, but the other had to be cut to match the wood of the lamp. First I traced the shape onto a short piece of 1" copper pipe using a caliper and a sharpie pen. I could have done the whole job, slowly, with a hand grinder or (even slower) a file, but with a new (to me) mill, that just seemed silly. I figured I could get close spinning the cranks freehand, so I clamped the pipe in a v-block and started in on it:

Remember Etch-A-Sketch, and how hard is to do angles and curves with it? Same here. Of course, I had to rotate the tube a few times but I got it close, then finished the job with few trial fittings and a Dremel flex shaft with HSS cutter.

Without the copper pipe it looks like this:

And the final result (two of a matched set of four for my cabin, the other two still in progress:

I would like to find a way to keep the copper shiny and bright. I'm told laquer, but I don't know what kind. Alcohol solvents (like in the shellac I use on the wood) are said to darken copper, but it hasn't (yet) on a test piece I shellacked.