-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

- Forums

- THE PROJECTS AREA

- PROJECT OF THE DAY --- WHAT DID YOU DO IN YOUR SHOP TODAY?

- Project of the Day Mega-Thread Archives

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2015 POTD Thread Archive

- Thread starter jumps4

- Start date

F

Firestopper

Forum Guest

Register Today

$400 sounds like a deal for V26 3 axis capabilities. Is it intuitive or similar to previous versions? Let see you machine.

- Joined

- Feb 8, 2014

- Messages

- 11,144

Yesterday I was walking out the side door in my shop and felt a slight temperature increase as I approached the door. Hmmmm, strange.  I started trying to track down the source and I put my hand on the breaker panel, right next to the door, and it was warm. Not a good thing. I grabbed my IR thermometer to get some readings. About 94 degrees on the front panel, the ambient temperature measured on the side of my tool box was 75.

I started trying to track down the source and I put my hand on the breaker panel, right next to the door, and it was warm. Not a good thing. I grabbed my IR thermometer to get some readings. About 94 degrees on the front panel, the ambient temperature measured on the side of my tool box was 75.  Pretty big difference given that I was not running any equipment in the shop, just the normal parasitic load of battery chargers, computers, and a couple of other minor loads, maybe 150 watts or so. It was getting late, and I was tired so I just shut off the main power feed to the shop.

Pretty big difference given that I was not running any equipment in the shop, just the normal parasitic load of battery chargers, computers, and a couple of other minor loads, maybe 150 watts or so. It was getting late, and I was tired so I just shut off the main power feed to the shop.

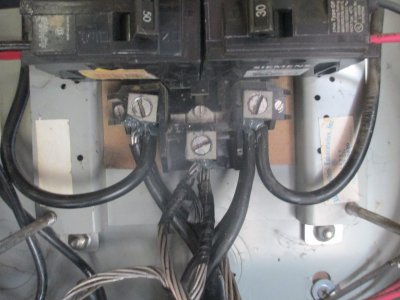

So this morning I pulled the cover off of the breaker panel, and turned power back on. I turned on all the lights and took temperature readings on all of the breakers and connections. It turns out that the right hand main power lug was getting hot, 74 to 108 degrees in about a half hour. The left lug remained at 74 degrees. The genius that wired the shop used aluminum wire and it was obviously getting oxidized. I know the guy, and he is a licensed electrician, I don't know how he has kept his licence, I've seen some of his other work. This was done before I bought the property, I would have brought in copper. The thing that he didn't do was use anti-oxidant compound on the aluminum wire.

I suspect I was just hours or maybe days away from an electrical fire in the shop. Ok, shut the power off again and check for a loose connection, everything was tight, so oxidation is the culprit. Off to HD to get a bottle of NOALOX to apply to the wires after I get them cleaned up.

Ok, shut the power off again and check for a loose connection, everything was tight, so oxidation is the culprit. Off to HD to get a bottle of NOALOX to apply to the wires after I get them cleaned up.

Now the aluminum wires are properly terminated, and have the proper amount of goo on them and the terminals. You use a small wire brush to de-oxidize and work the compound into the wire. The screws are tightened then tightened again, then at least one more time.

I did a load test after I did the repairs, with all the lights on and the compressor coming up from empty the terminals stayed at ambient temperature. I think that one is fixed.

While I was at HD I picked up a new set of IR motion detectors for my shop yard lights. One of them was dead and the the other was getting weak. Got those installed so now when I come out of the shop in the dark, at least I have a chance of not walking into something. After being in a well lit shop, then walking into the dark it takes a while for my old eyes to adjust, it's like midnight in a coal mine. You can wire these parallel, I didn't know if that would work, so I just tried it. Didn't let the magic smoke out.

Pretty big difference given that I was not running any equipment in the shop, just the normal parasitic load of battery chargers, computers, and a couple of other minor loads, maybe 150 watts or so. It was getting late, and I was tired so I just shut off the main power feed to the shop.

Pretty big difference given that I was not running any equipment in the shop, just the normal parasitic load of battery chargers, computers, and a couple of other minor loads, maybe 150 watts or so. It was getting late, and I was tired so I just shut off the main power feed to the shop.So this morning I pulled the cover off of the breaker panel, and turned power back on. I turned on all the lights and took temperature readings on all of the breakers and connections. It turns out that the right hand main power lug was getting hot, 74 to 108 degrees in about a half hour. The left lug remained at 74 degrees. The genius that wired the shop used aluminum wire and it was obviously getting oxidized. I know the guy, and he is a licensed electrician, I don't know how he has kept his licence, I've seen some of his other work. This was done before I bought the property, I would have brought in copper. The thing that he didn't do was use anti-oxidant compound on the aluminum wire.

I suspect I was just hours or maybe days away from an electrical fire in the shop.

Ok, shut the power off again and check for a loose connection, everything was tight, so oxidation is the culprit. Off to HD to get a bottle of NOALOX to apply to the wires after I get them cleaned up.

Ok, shut the power off again and check for a loose connection, everything was tight, so oxidation is the culprit. Off to HD to get a bottle of NOALOX to apply to the wires after I get them cleaned up.

Now the aluminum wires are properly terminated, and have the proper amount of goo on them and the terminals. You use a small wire brush to de-oxidize and work the compound into the wire. The screws are tightened then tightened again, then at least one more time.

I did a load test after I did the repairs, with all the lights on and the compressor coming up from empty the terminals stayed at ambient temperature. I think that one is fixed.

While I was at HD I picked up a new set of IR motion detectors for my shop yard lights. One of them was dead and the the other was getting weak. Got those installed so now when I come out of the shop in the dark, at least I have a chance of not walking into something. After being in a well lit shop, then walking into the dark it takes a while for my old eyes to adjust, it's like midnight in a coal mine. You can wire these parallel, I didn't know if that would work, so I just tried it. Didn't let the magic smoke out.

F

Firestopper

Forum Guest

Register Today

Jim,

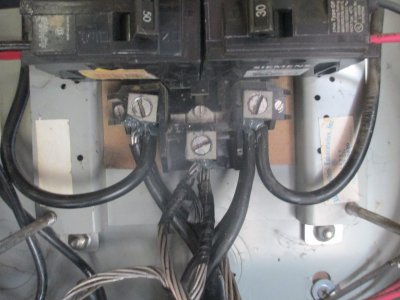

man, its a good thing you caught that before a fire broke out. Noalox is a must with Aluminum, I used heavy aluminum feeders to the 200Amp panel and made sure to dab that magic sauce on the terminal lugs. Hard to see in photo but its there. The bud light came after the work i assure you hahaha.

Costco had some 2000 lumen LED IR motion on sale some time back for 38 bucks after rebate. They work great.

Again, nice catch on the breaker panel.

man, its a good thing you caught that before a fire broke out. Noalox is a must with Aluminum, I used heavy aluminum feeders to the 200Amp panel and made sure to dab that magic sauce on the terminal lugs. Hard to see in photo but its there. The bud light came after the work i assure you hahaha.

Costco had some 2000 lumen LED IR motion on sale some time back for 38 bucks after rebate. They work great.

Again, nice catch on the breaker panel.

F

Firestopper

Forum Guest

Register Today

- Joined

- Dec 8, 2013

- Messages

- 2,651

I use aluminum whenever I can for power distribution. However, I also always use CU/AL connectors, antioxidant, and a torque wrench.The genius that wired the shop used aluminum wire and it was obviously getting oxidized. I know the guy, and he is a licensed electrician, I don't know how he has kept his licence, I've seen some of his other work. This was done before I bought the property, I would have brought in copper. The thing that he didn't do was use anti-oxidant compound on the aluminum wire.

Note that the utility companies don't use copper.

- Joined

- Feb 8, 2014

- Messages

- 11,144

I use aluminum whenever I can for power distribution. However, I also always use CU/AL connectors, antioxidant, and a torque wrench.

Note that the utility companies don't use copper.

I agree John, aluminum is fine for mains if properly installed. If it's not installed correctly, it's a fire hazard.

- Joined

- Feb 24, 2015

- Messages

- 1,382

That is one neatly wired load center, Paco.

I found that even copper wire connections can get loose and heat up. The big crimped inline connectors from the power pole to the lead wires of my meter got loose and heated so much they melted the plastic covers off them.

I found that even copper wire connections can get loose and heat up. The big crimped inline connectors from the power pole to the lead wires of my meter got loose and heated so much they melted the plastic covers off them.

- Joined

- Feb 10, 2014

- Messages

- 366

Note that the utility companies don't use copper.

And they are always fixing their grid.

Sent from my iPhone using Tapatalk