- Joined

- Feb 17, 2013

- Messages

- 336

I have been trying to buy the rotary table option for my 8" Vertex super spacer and not had any luck finding one for a reasonable price. I decided to make one. I started out with a 12" round steel plate that I bought as scrap and a 13.3" GM truck brake rotor. Here's the S.S. without the chuck. as you can see there is a raised boss in the middle to locate the chuck. The boss measures 6.295" and is .200" high.

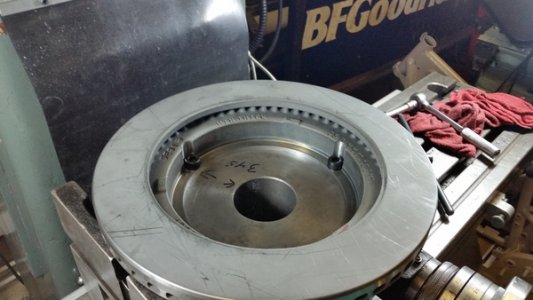

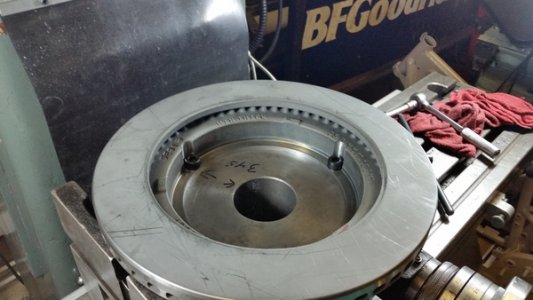

Then the brake rotor sitting on it.

First I put the rotor in the lathe to whittle it down to 12" from 13.5" and remove most of the metal from one side of the braking surface to provide clearance on the S.S. I didn't get any pics of that process but it made a big mess of cast iron chips.

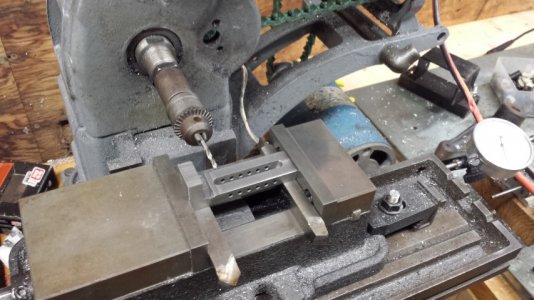

Then I mounted the chuck back on the S.S. and used the mill and a 3/8" roughing end mill to carve out the center of the rotor to a rough dimension close to the 6.297" I was aiming for then I used a finishing end mill for the final cut and hit the dimension perfectly.

A perfect fit!

Then I located and drilled the 3 bolt holes in the rotor to align with the existing chuck bolt holes in the S.S. I then used a 3/4" end mill from the other side to provide clearance for the 10mm socket head cap screws.

I used a 1/4 chamfer end mill to radius the edges top and bottom.

Then I drilled 6 holes for 8mm shcs's into the steel round plate and tapped the holes in the rotor and bolted the plate to the rotor and mounted the whole assembly in the lathe and faced the plate off nice and flat. the bolt heads are counter sunk .020" below the surface of the plate.

There are 4 existing 5/8" threaded holes on the plate and I added another unthreaded 5/8" hole to the center while it was in the lathe. You can still see some shadows from a piece that was welded to the plate but you can't feel them.

Then it went back to the mill where I drilled and tapped twenty two 3/8" holes for hold downs.

Now to make the hold down straps and studs, that will be another day. The I can get started on the project that motivated me to make the rotary table.

Then the brake rotor sitting on it.

First I put the rotor in the lathe to whittle it down to 12" from 13.5" and remove most of the metal from one side of the braking surface to provide clearance on the S.S. I didn't get any pics of that process but it made a big mess of cast iron chips.

Then I mounted the chuck back on the S.S. and used the mill and a 3/8" roughing end mill to carve out the center of the rotor to a rough dimension close to the 6.297" I was aiming for then I used a finishing end mill for the final cut and hit the dimension perfectly.

A perfect fit!

Then I located and drilled the 3 bolt holes in the rotor to align with the existing chuck bolt holes in the S.S. I then used a 3/4" end mill from the other side to provide clearance for the 10mm socket head cap screws.

I used a 1/4 chamfer end mill to radius the edges top and bottom.

Then I drilled 6 holes for 8mm shcs's into the steel round plate and tapped the holes in the rotor and bolted the plate to the rotor and mounted the whole assembly in the lathe and faced the plate off nice and flat. the bolt heads are counter sunk .020" below the surface of the plate.

There are 4 existing 5/8" threaded holes on the plate and I added another unthreaded 5/8" hole to the center while it was in the lathe. You can still see some shadows from a piece that was welded to the plate but you can't feel them.

Then it went back to the mill where I drilled and tapped twenty two 3/8" holes for hold downs.

Now to make the hold down straps and studs, that will be another day. The I can get started on the project that motivated me to make the rotary table.