This has been a couple day project, not just today. On background, my son, the entrepreneur, makes and sells balsa airplane kits and other stuff for them One of the products is a clutch that goes between the propeller and the drive shaft, so that when the motor quits (read when the rubber band unwindes) the prop will spin free rather than trying to wind up the rubber band. He sells them for prop shafts of 3/64, 1/16, 2 mm and 3/32. When he bought Superior Props, the business that supplied these, there was a pretty good invenory of them. After two years, that inventory has mostly been sold and I've been tasked to make more. The two smaller sizes are identical except for the hole through the middle, that is a clearance hole for the prop shaft. They each have a 5-40 1/8 set screw to hold the clutch to the prop shaft, and two holes for .032 wires which operate the clutch mechanism. The two small sizes are made form 1/4" Aluminum rod.

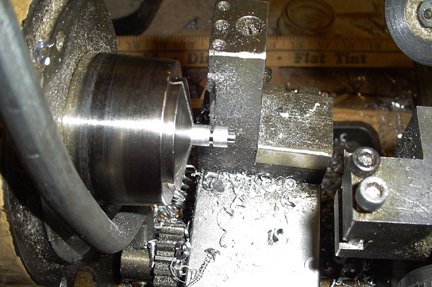

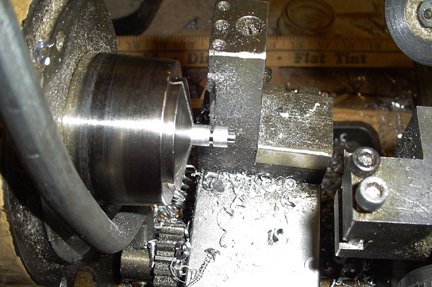

I start out in the turret lathe turning the parts.

It's not quite cut off here. It's been center drilled, drilled through, necked to .125 and the corners have been broken with a file. Each one takes maybe a minute. Note the cut off tool is upside down in the back

They look like this after parting off. .

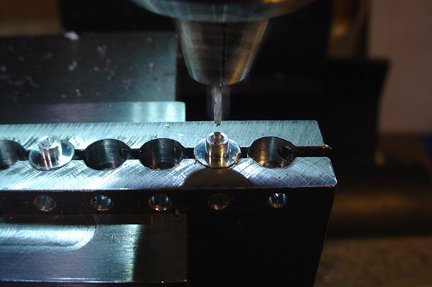

From here they go to a drill fixture for drilling the hole for the tap and for drilling the two .038 holes. I made a gang fixture for this.

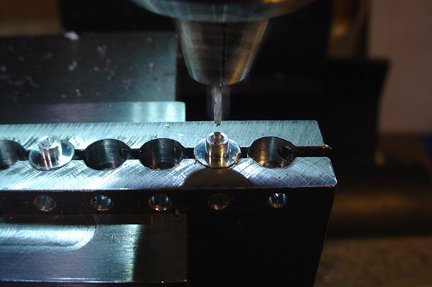

This is the .101 tap drill for the 5-40 set screw. (typo edited)

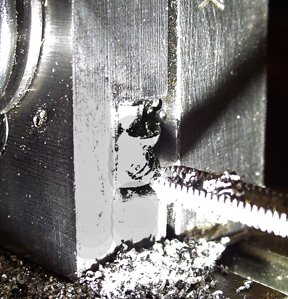

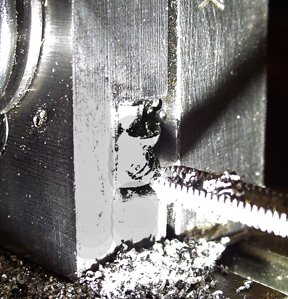

Next is to drill the two .038 holes one on center up .100 the other up .080 and over .045.

I was testing the fixture and the drill, didn't want to scrap too many if it didn't work.

This is the tapping machine, Some might recognize the unit under the mounting block.

And a pretty poor shot of the part having been tapped. (look for internal threads)

Here's the finished clutch, set screw, two wires and all, ready to go. About 3 Dozen were sold last year of this size.

Remember, that's a 5-40 set screw,the wires are .032, the whole thing is .270 long. I've got 4 dozen turned.