- Joined

- Feb 22, 2013

- Messages

- 159

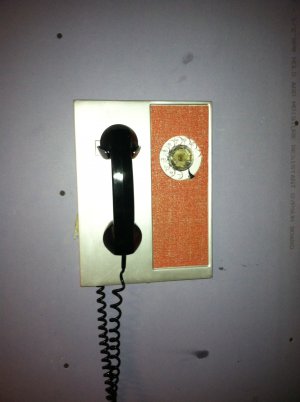

Well after too many times of either not hearing my cordless phone or bringing it into the shop and forgetting to take it back upstairs I purchased a phone for the shop. I went a little different. Got a nice old panel mount phone with a mechanical ringer that's loud as hell. No more not hearing that anymore. I had to fab a housing to mount it in the wall and do a general taking apart and cleaning of all the mechanicals. Unfortunately I have VoIP so I cannot dial out because my phone modem does not recognize pulse dialing. It answers and rings fine though. I have a pulse-to-tone converter coming to make it 100% functional again.