-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

- Forums

- THE PROJECTS AREA

- PROJECT OF THE DAY --- WHAT DID YOU DO IN YOUR SHOP TODAY?

- Project of the Day Mega-Thread Archives

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2016 POTD Thread Archive

- Thread starter sanddan

- Start date

T

TOOLMASTER

Forum Guest

Register Today

- Joined

- Feb 2, 2014

- Messages

- 1,069

I bought some of the cheapest inserts ($2.19 each) I could find on Enco to do some experimenting. I used one for my ball turner #3 that cuts steel nicely.

I used one today to make a boring bar for my lathe.

Made from a piece of 5/8" rod, a roll pin, and a 8X32 screw.

After grinding a relief for the end of the insert I chucked up a piece of mild steel. I started by truing up the inside of the 1" hole that was already there. I then took a 0.010 cut and it looked nice. I wanted to see just how much I could take off so increased the cut to 0.020, 0.030, and then 0.040. The finish got even a little better but I stopped there as I couldn't see me wanting to take off more than 0.080 in a single pass. A second pass at the same setting showed about 0.05 more was removed. This is a huge difference from what I was used to with my cheap springy boring set from HF. I may try to make a 1/2" bar also.

Thanks for looking

Ray

I used one today to make a boring bar for my lathe.

Made from a piece of 5/8" rod, a roll pin, and a 8X32 screw.

After grinding a relief for the end of the insert I chucked up a piece of mild steel. I started by truing up the inside of the 1" hole that was already there. I then took a 0.010 cut and it looked nice. I wanted to see just how much I could take off so increased the cut to 0.020, 0.030, and then 0.040. The finish got even a little better but I stopped there as I couldn't see me wanting to take off more than 0.080 in a single pass. A second pass at the same setting showed about 0.05 more was removed. This is a huge difference from what I was used to with my cheap springy boring set from HF. I may try to make a 1/2" bar also.

Thanks for looking

Ray

F

f350ca

Forum Guest

Register Today

- Joined

- Aug 29, 2013

- Messages

- 1,050

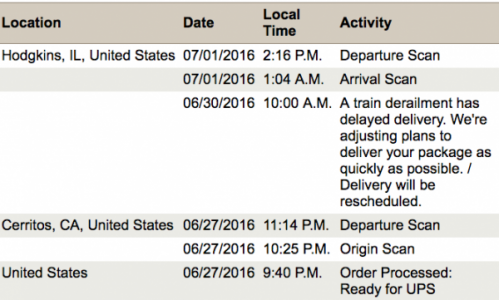

This morning the wife and I went for a nice drive up to the town of Rutland. They have one of those guys that has a perpetual garage sale. Well now I guess he's selling the building, which looks like it was one time a three-bay commercial garage. He didn't have much in the way of tools, but I did get a nice old cast iron pipe cutting clamp and some other stuff. I missed the pipe bender which somebody got to just before me. I told the guy I was looking for bar stock and hardware. He said he usually gave all steel stock he found to a woman who was a welder (boy, that would be handy). He did show me a plastic tub that had some nuts, washers, etc. that were semi-organized. I had a nice find - a box of 7/16-14 hex head bolts, 2" long. What made it nice is that they were from Reed & Prince in Worcester. I bought them of course.

They had some rust on them, but I put them in the tumbler with my swarf-and-motor-oil mix. About 120 minutes per batch:

They were made here:

This from over ten years ago:

"Disposition of the Property

The 10.5 acre industrial mill site will be redeveloped into a 68, 652 - sq/ft Price Chopper Supermarket. The project required the demolition and removal of the existing 230,250 - sq/ft industrial mill complex."

The supermarket has been there for at least ten years.

Oh well, at least the company is still making fasteners here in Massachusetts.

By the way, "Reed" was from the same family that made Reed & Prentiss and Vernon metal lathes.

They had some rust on them, but I put them in the tumbler with my swarf-and-motor-oil mix. About 120 minutes per batch:

They were made here:

This from over ten years ago:

"Disposition of the Property

The 10.5 acre industrial mill site will be redeveloped into a 68, 652 - sq/ft Price Chopper Supermarket. The project required the demolition and removal of the existing 230,250 - sq/ft industrial mill complex."

The supermarket has been there for at least ten years.

Oh well, at least the company is still making fasteners here in Massachusetts.

By the way, "Reed" was from the same family that made Reed & Prentiss and Vernon metal lathes.

- Joined

- Jan 22, 2011

- Messages

- 8,031

Greg, I'm somewhat envious of you guys who have the setup to handle raw logs and end up with nice finished projects. Here in East Texas, we have mostly softwoods, but there are some good Oaks to be had. And there are a few guys with portable sawmills that will come rough saw it out. The problem comes (for me at least) a place to store the rough wood until it can be safely worked. I have all the tools to take it from rough wood to finished product, but I need an entirely separate building for that. And since my shop is my living, I can't justify building a wood shop. If I had that much excess funding, it would probably go to improve or expand the business. That's another thing I envy about the hobbyists here.....just the fact that metalwork is a hobby. It's different when it's a livelihood. For me, the woodworking would be the hobby, and I don't have the time or money for that intense a hobby yet..

BTW, the tables look great!

BTW, the tables look great!

T

TOOLMASTER

Forum Guest

Register Today

just sliced my toe open

- Joined

- Jul 21, 2015

- Messages

- 566

Nice looking tables. People just don't do it that way any more.