POTD was a “real” job shop project. I’m a quality engineer at the Lansing Grand River Assembly Plant in Lansing, MI. We make Cadillac ATS, CTS and Chevy Camaros. I own a number of the exterior parts on the cars. We noticed this past Friday that what we call the daylight opening (DLO) molding fit to the quarter glass wasn’t fitting perfectly. It was within the quality standard, but didn’t fit as nicely as we would like.

The quarter glass is urethaned to the car body, then the DLO is slid onto a bayonet that extends from the quarter glass. The DLO is then pop riveted to the body. So, problem in the DLO, quarter glass, body or assembly process?

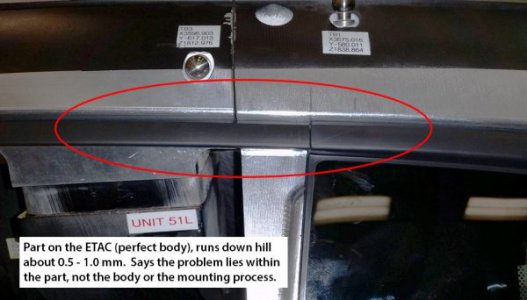

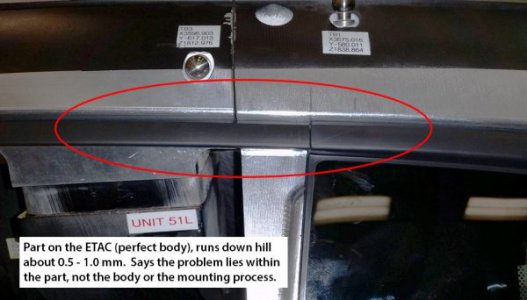

We have a problem solving tool called the ETAC which is a machined aluminum “perfect body”. All of the panels/details are removable so if we are evaluating a fender to hood fit (for example), the perfect hood can be removed and a production one installed and fits compared to the perfect fender. In my case, the DLO was set on the perfect body side of the car and the issue was within the part.

The DLO is an aluminum extrusion that is stretch bent to shape. From the last rivet attachment to the body it was running downhill about 1 mm. I put some washers above the last rivet attachment to create a gap between the ETAC and the very end of the part. Measured the gap between the DLO and ETAC, then pushed up and bent the DLO so the gap was 1 mm less. Removed the washers and reinstalled the part; perfect fit.

OK, now how do we modify parts at a line rate of 24 Camaro’s per hour at a plant that runs from Sunday night at 9:30 PM through Friday night at 11:30 PM? Oh, the tool room doesn’t have a second shift; looks like I have a POTD at home. . .

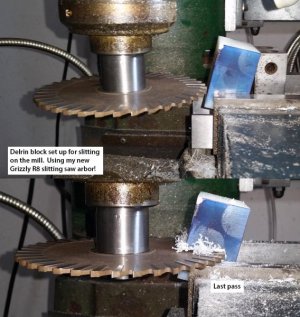

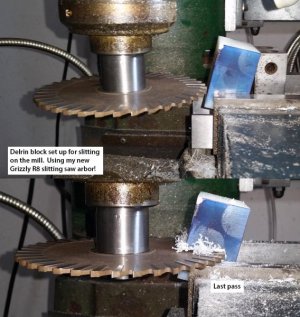

Pictures show the bending fixtures from my shop. Used delrin for the base to keep from scratching the DLO. The DLO’s will be dropped into the fixture and hand bent up to the stop. Our supplier is working the problem so we won’t be hand bending parts for too long; we typically have a week’s worth of parts on hand so roughly 6000 parts to rework. Guess what I’ll be doing during the football games today? Line starts at 9:30 PM tonight, want to give our customer’s the best product we can.

Bruce