- Joined

- Jan 25, 2015

- Messages

- 2,558

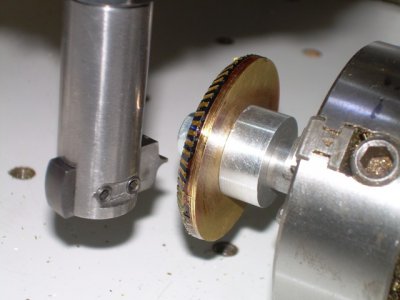

I'll be making a "schaublin" style collar for use with my next backing plate on my Atlas to keep the chuck from turning off in reverse.I wonder if he did something custom.

Looks like this:

My issue is going to be cutting the threads. I haven't cut any threads at all on the lathe as of yet.

Gonna have to figure it out though. I need to cut metric threads and from what I understand, I'll need to run the lathe in reverse in order not to mess up metric threads....

Last edited:

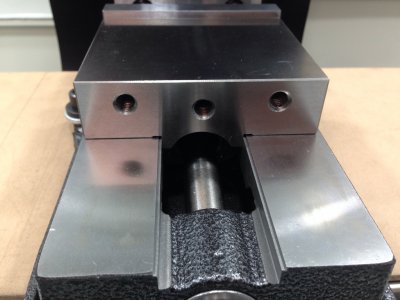

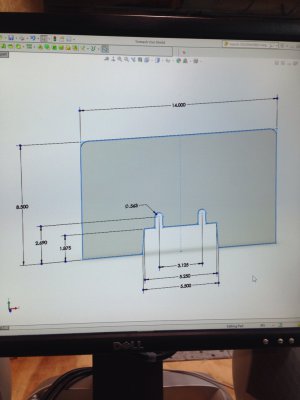

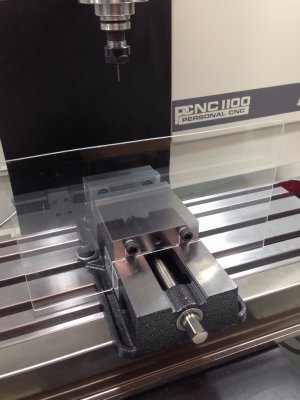

which was to make a chip shield for the 1100 vise from this pc of plastic I found.

which was to make a chip shield for the 1100 vise from this pc of plastic I found.