-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

- Forums

- THE PROJECTS AREA

- PROJECT OF THE DAY --- WHAT DID YOU DO IN YOUR SHOP TODAY?

- Project of the Day Mega-Thread Archives

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2016 POTD Thread Archive

- Thread starter sanddan

- Start date

Not sure how mid neck tuning will be..

Is that about the guitar I posted? I have already done the dry fit and it seems to play and tune quite well. I am in the process of addressing one or two frets that need some work and getting the pickups working, but I am confident it will turn out well.

That is a great clamp that you made!!!

Now you've done it; I have to repair my 16" shaper. All wiring was cut between the motor and controls. I should have worked on the shaper instead of buying a broach set to cut a keyway in a gear that I'm making. Would have been $$'s ahead and have the shaper to use. Post some info on your shaper if you get a few minutes

F

f350ca

Forum Guest

Register Today

Thanks Reeltor, here's a link to the posts I did when I was getting it going, was in sorry shape when I brought it home.

http://www.hobby-machinist.com/posts/336347/

Greg

http://www.hobby-machinist.com/posts/336347/

Greg

- Joined

- Jun 15, 2013

- Messages

- 1,199

Was a busy night in the shop, I have another project to show but I have to finish some modeling first.

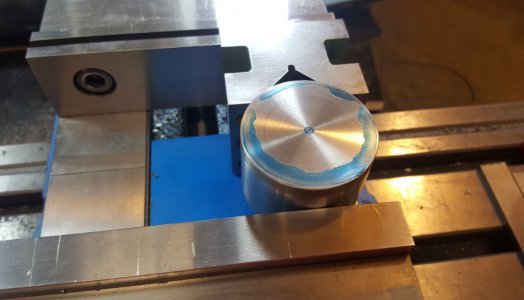

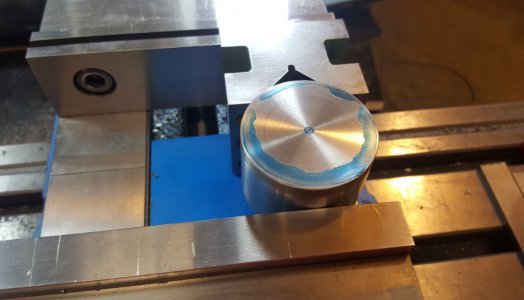

Here is a cast iron lap that is specially made for Ariel JGP compressor valves, its about 2 inches is diameter, 1.49 thick, the squares are .200/.200 .030 deep, I started with a squarish/hex shaped block, moved it until the sharpie center was somewhat in the middle, around .010 runout I spose, drilled and tapped for a shaft I had turned, which be used to hold to turn the O.D. as well as for power lapping. i scraped it flat then brought it in to bearing, i was happy with the final spot, and put the grooves in with a 1/4 in chamfer end mill 90deg. it works really well, and will save the company i work for quite a bit of money, of course we will still have to send some valves to a shop when they have to be turned, but most of em will lap flat, sand really takes out the sealing surface of both the valve and valve disk, which is made of a type of plastic. here shown is a valve body i have lapped using 400gr and a hand drill

Here is a cast iron lap that is specially made for Ariel JGP compressor valves, its about 2 inches is diameter, 1.49 thick, the squares are .200/.200 .030 deep, I started with a squarish/hex shaped block, moved it until the sharpie center was somewhat in the middle, around .010 runout I spose, drilled and tapped for a shaft I had turned, which be used to hold to turn the O.D. as well as for power lapping. i scraped it flat then brought it in to bearing, i was happy with the final spot, and put the grooves in with a 1/4 in chamfer end mill 90deg. it works really well, and will save the company i work for quite a bit of money, of course we will still have to send some valves to a shop when they have to be turned, but most of em will lap flat, sand really takes out the sealing surface of both the valve and valve disk, which is made of a type of plastic. here shown is a valve body i have lapped using 400gr and a hand drill

Greg,Thanks Reeltor, here's a link to the posts I did when I was getting it going, was in sorry shape when I brought it home.

http://www.hobby-machinist.com/posts/336347/

Greg

Great job on your shaper. After looking at the post on the rebuild I am embarrassed that mine has been sitting and not doing work. Cleaning starts after work tomorrow

- Joined

- Jun 15, 2013

- Messages

- 1,199

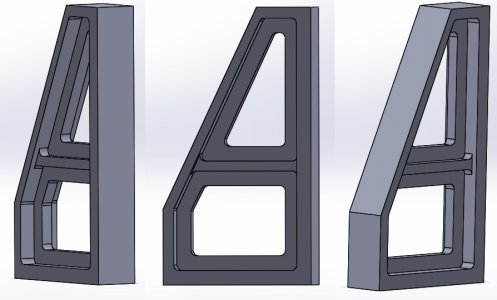

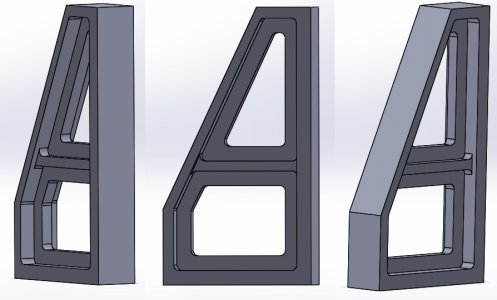

Here is the other project I made mention of above, first is the cast iron lap, ive showed it before but it was unfinished, broken tool, its about 11x6x1.5, with a diagonal cross hatch done on the cnc, I finally got around to finishing it, in hopes I can get paid for it. Sitting atop of it is a 9.5x5.1x1.5 semi-machined cast iron square, the to-be-scraped faces are to be .500 thick (front/bottom), the top, angle, and back faces are .375, the pockets are .550 deep, with the strut being .350 tall, leaving the web .397. All the radii are .1875, not shown, or modeled is all the floor radii, not sure if I will use a 3/8 or 1/4 ball nose to do them, haven't decided. reason they are not modeled is I will use this model for the machining, or CAM and there is no need to complicate things, or overmodel.