T

TOOLMASTER

Forum Guest

Register Today

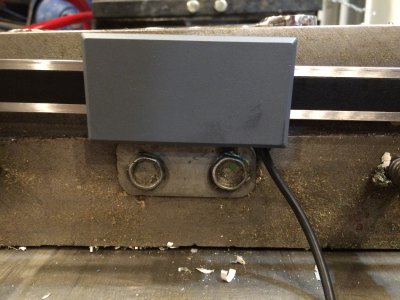

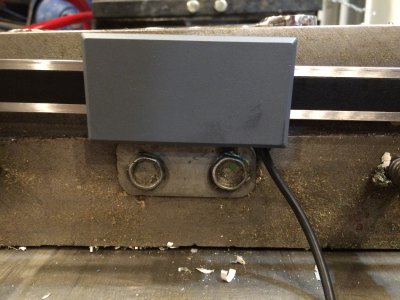

after 15 years I finally got a (1) dro on my mill..never really needed on for the stuff i do at home but it is nice to have..

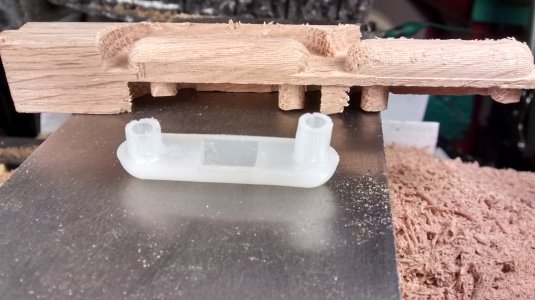

went on pretty easy.. used the center existing bracket to mount the unit and removed the stops and used those to mount the end brackets.

pulled the vise for the second time in 15 years to..lol got it back straighter than it has ever been..i don't normally worry about it but the last thing i made came out worse than I thought, since it was a long piece with holes down the middle :-/

went on pretty easy.. used the center existing bracket to mount the unit and removed the stops and used those to mount the end brackets.

pulled the vise for the second time in 15 years to..lol got it back straighter than it has ever been..i don't normally worry about it but the last thing i made came out worse than I thought, since it was a long piece with holes down the middle :-/