I’m in the (slow) process of making a sine plate for my mill, it’s the one with an aluminum bar big enough to rise above the jaws of the vise, with a flat plate recessed into it. I had started to mount the plate in the cut-out in the bar, and found I didn’t have a counter sink big enough for my 3/8 flathead screws. To make a long story short I made one (well it’s not hardened and drawn, but it’s ‘made.’

! started with a piece of 13/16 hot rolled 4140 2 ¼ long, turned the shank down to .500, and turned a 82º cone on the other end. I also took a skin cut to get under the hot rolled surface. I drilled out a ½ - 13 nut and put a set screw in it to make my Hex block.

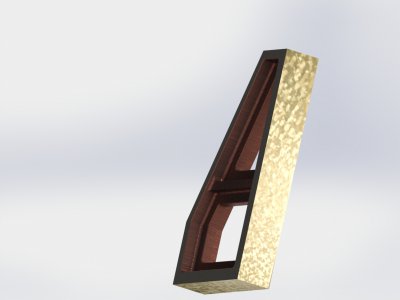

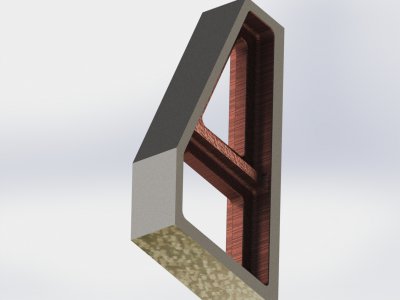

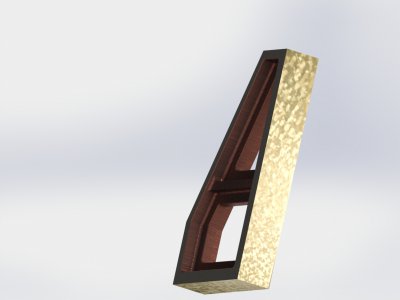

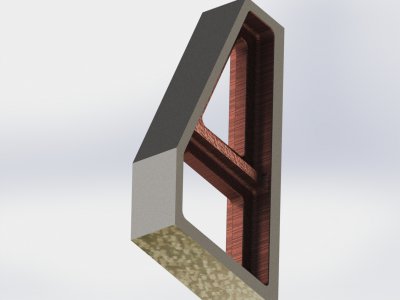

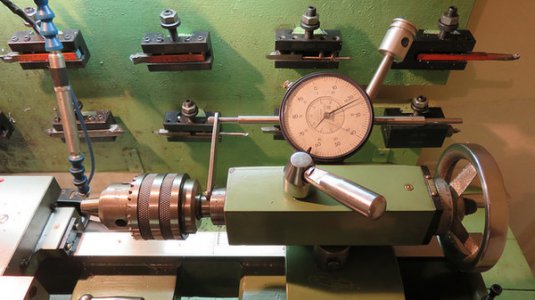

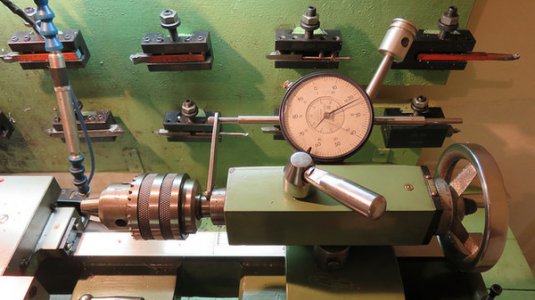

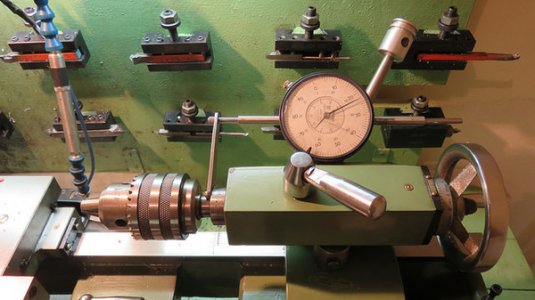

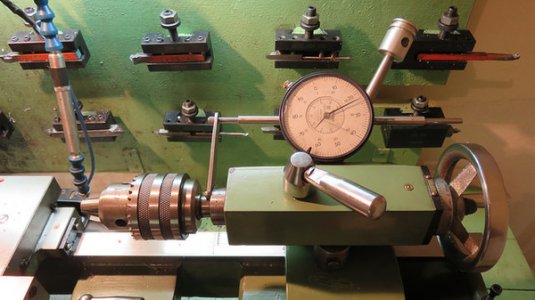

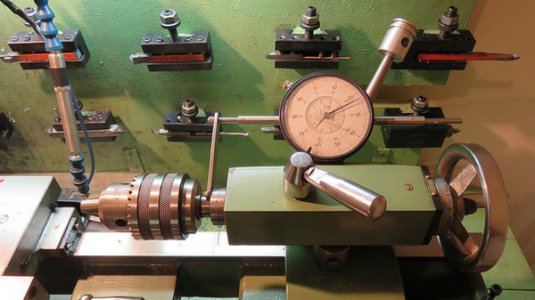

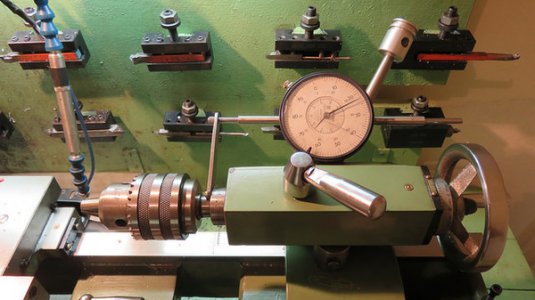

I figured out that the 9/16 counter sink I had had been held in the mill at a 12º angle for milling the flutes, so I set my piece at that angle, shimming under it so it wouldn’t change angle (yeah, it did before I shimmed it.) Here’s a shot of it in process.

And here it is still hot from the cutter, along side my 9/16 countersink that inspired the new one. I know, the center isn’t perfect, but it’s made to cut, not be pretty.

I intend to harden it to cherry red, quench it in old motor oil and (having washed all the oil off) bake it in the oven at 450º for a while. I think I’ll do a little hand relieving and polishing on the cutting edge before I harden it.

Anyway, now I can countersink my 3/8 flat head screws.