- Joined

- Jul 26, 2013

- Messages

- 584

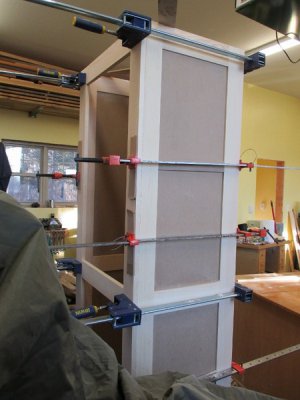

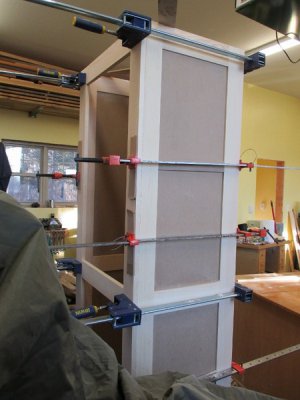

I was working on a cabinet over the last couple of days. Here's a few shots of the glue-ups...

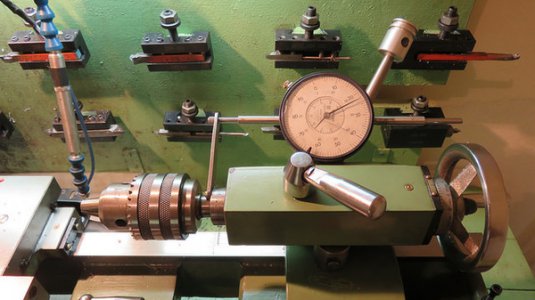

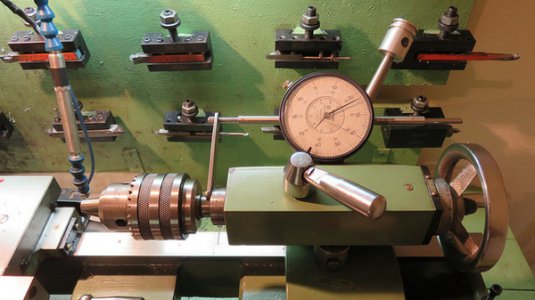

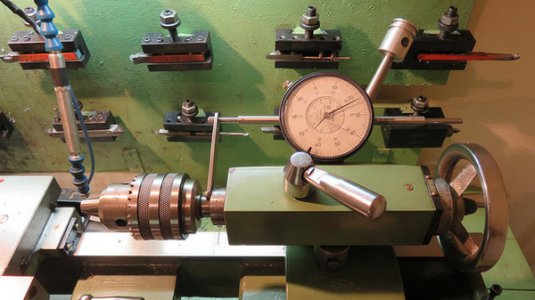

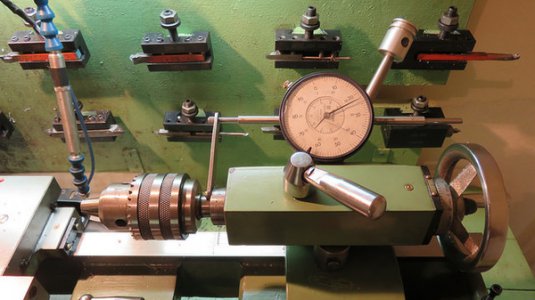

Here, I'm forming tenons on the rails for the doors...

And here, I just finished gluing up the two doors....

It's a fairly simple cabinet made out of pine with 1/4" MDF panels, but all of the joints are full mortise and tenon for strength. It will be painted when finished.

Brian

Here, I'm forming tenons on the rails for the doors...

And here, I just finished gluing up the two doors....

It's a fairly simple cabinet made out of pine with 1/4" MDF panels, but all of the joints are full mortise and tenon for strength. It will be painted when finished.

Brian